ABS steel is mainly used in the automotive industry, where it has a broad range of applications throughout the supply chain of creating and maintaining vehicles.

Whether it’s wire rods, ingots, rolled billets, forged bars or rotoforged products, each unique process requires carefully controlled heat to activate the chemical reactions that change ore into the extraordinary.

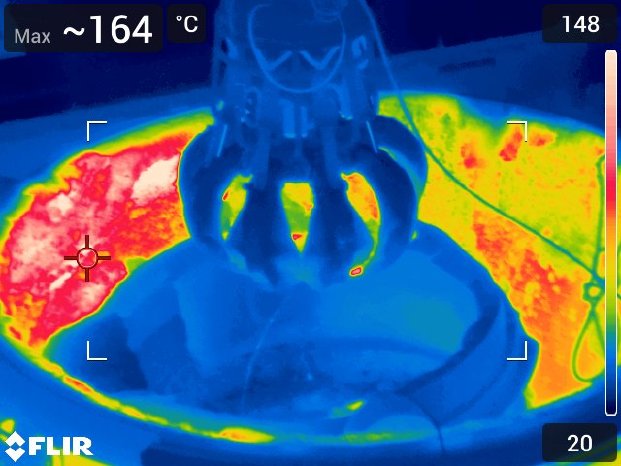

In the intense environment needed to mould steel (which melts at temperatures above 1200°C) it’s no surprise that it can take considerable supplies of energy to create sufficient heat as the ore is slowly melted, purified and recast into the desired shape and form.

Cutting costs with cutting-edge tech

With energy prices rising across Europe, ABS is taking action to actively cut maintenance costs across the board - with the help of cutting-edge Teledyne FLIR technology.

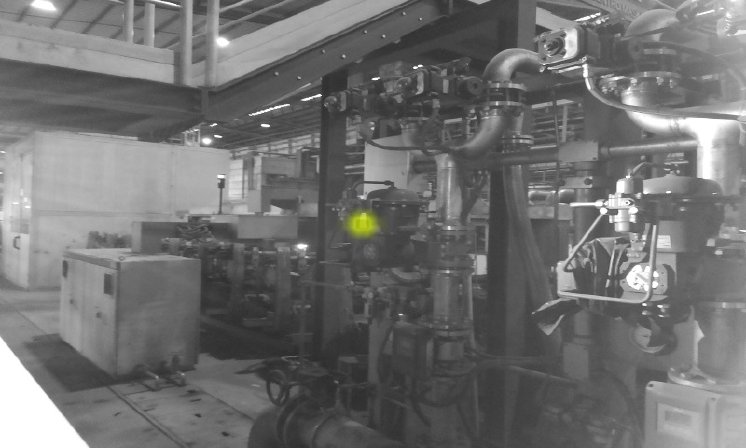

ABS’ Udine factory has a direct supply of electricity from the Italian power grid to drive an induction furnace which is used to melt ore and recycled materials into shaped steel. The site receives electricity through an on-site substation, and uses compressed air extensively throughout the production process to power many manually repetitive operations - such as moving sections of a metal bar that has been cut to length into bundles, or coiling operations.

The compressed air systems run through the entire length of the production operation with hundreds of couplings, filters and actuators - each with the potential to leak. For such energy-intensive industries, even the most minute air leak can lead to substantial energy wastage, costing more to power the machinery optimally and driving up production costs with every m³ of air lost.

Pinpoint and patch air leaks before they cost you money

This is where inventive solutions provide a unique line of defence for locating and sealing air leaks and keeping the facility at maximum efficiency.

By using the FLIR Si124 acoustic camera, ABS can detect and isolate compressed air leaks, corona and partial discharge throughout the production facility and substation, enabling engineers to ensure a reliable and uninterrupted energy supply while simultaneously managing their compressed air system before air loss can begin to negatively impact their energy bill.

Acoustic imaging is specifically designed to enable operators to see the energy lost through air leaks by transposing an image based on the inaudible ultrasonic vibrations picked up by the 124 cutting-edge acoustic microphones in situ, even in loud industrial environments which can often mask maintenance issues.

So, whatever size the air leak, it can be instantly flagged and fixed.

Daniele Guastamacchia, head of maintenance engineer at Acciaierie Bertoli Safau SpA, explains the benefits of using both active thermography and acoustic imaging to increase productivity and reduce cost.

“I’ve been working with ABS for five years, and I immediately noticed that the company was very responsible with research and predictive analysis. Quality predictive research has always been closely correlated to the thermographic field and ultrasound analysis, which is why we chose to buy a FLIR T865 and Si124. The Si124 in particular is very easy to use and doesn’t require much experience; it’s all very intuitive. As a thermographic and sonic camera, its usefulness in the energy field and consequent costs reduction cannot be overstated - especially now when suppliers are paying drastically more per kWh. Specific tools like this one really do help underline key savings to our bottom line”.

To securely back-up and share files and findings about their energy performance and quality control, ABS uses FLIR IGNITE™ cloud-based file transfer system. What’s more, to easily quantify energy saved in clear terms, ABS uses FLIR Thermal Studio reporting software for trend analysis and maintenance requirements. “Using Thermal Studio is inevitable really,” adds Daniele, “because it gives us the opportunity to edit the files as needed and to file reports quickly and incredibly easily. It’s really useful!”