Innovative shoes.

Both the footwear and the garment industry are fast growing parts of the economy. To react to the rapidly changing trends and fashions is one of the most important market requirements that the footwear industry has to face. Another challenge is to frequently supply stores with the latest products. In order not to lose a customer, orders have to be fulfilled quickly and dynamically. Today's distribution centres of large retailers supply hundreds of stores on a daily basis shipping millions of pairs of shoes a week. Traditional manual distribution centres are no longer able to efficiently handle such quantities of goods quickly and effectively.

NG2 Group is the leading Polish footwear retailer and one of its biggest shoe producers in Poland. Currently the NG2 Group has a network of 708 stores, including stores of famous brands such as CCC, Boti and Quazi. NG2's estimated market share in the Polish footwear retail is around 10 percent. Statistically Polish citizens buy 3.5 pairs of shoes per capita and year. This compares to the 5 pairs of shoes bought by an average Western European per year, illustrating the potential for growth in the Polish market.

The NG2 distribution centre was traditionally semiautomated with a forklift truck operated pallet warehouse, shelf racks and a sorting installation with a sorter and conveyor system. As a result of the company's decision to heavily invest in the logistics operations, that existing installation will soon be enlarged and upgraded with building of an automated warehouse. "The decision to implement automated warehouses was already made several years ago. It was the logical answer to the need of improving efficiency and to the dynamic growth of the CCC retail network" says Mariusz Gnych, NG2's board vicepresident.

In subsequent periods the company has decided to launch other networks: Quazi boutiques and Boti shoe shops. It became clear that only efficient logistics would enable a smooth development and help the company keep their leading position in the Polish footwear market. "We decided to launch a sorting hub and to increase the warehouse capacity" (currently 50,000 sq m).

The first step toward automation of the logistics processes was the implementation of a sorting system for footwear last year. The system allows for fast allocation to the entire sales network according to the longterm development strategy. The success of automated distribution of footwear resulted in further efforts to optimize the warehouse management. As a result of these efforts a miniload warehouse is going to be constructed, which will be the largest of its kind in Central and Eastern Europe.

In order to enable further expansion and to improve the logistics processes NG2 decided to invest in a new distribution centre which is to start operations at the turn of 2011/2012. Austrian company TGW was chosen as general contractor of this highly automated logistics system. The requirements for this new automated warehouse project included maximized storage capacity, accurate and effective picking and the adaptation to the company's growth strategy.

Key to the success of an investment in automatic logistics processes is the selection of a competent and experienced solutions provider. Therefore, the choice may not be intuitive but based on a solid basis and the request for proposal should be precisely defined. Typically such requests are answered by many bidders. In this case NG2 was looking for a supplier in Poland and abroad who would dispose of an integrated solution including the miniload warehouse system with compatible software. According to Mr. Gnych special emphasis was put on the quality of the offered solutions, references in similar ventures and - most importantly - the price. "The offer submitted by TGW Logistics Group GmbH scored best. Thanks to this decision TGW will equip the new warehouse with racks, stacker cranes, conveyors and software."

TGW is a systems integrator for automated warehouse solutions headquartered in Austria, which provides technologically advanced and tested systems for the transportation and storage of carton boxes. Since 2000 the TGW Group has delivered over 50 systems allowing for direct transportation and storage of cartons. Automated solutions, especially miniload systems are the basis for the 40 year's corporate history.

NG2 decided to follow the trend in the textile distribution to directly handle cartons throughout the supply chain. What was the reason for choosing the present solution rather than using a pallet warehouse? "A constant monitoring of the latest trends and the available logistics technologies showed that a solution with an automated warehouse operated by stacker cranes would be the optimum for a comprehensive logistics service in the footwear industry", says NG2's vicepresident.

Based on the experience of the companies in related industries which are using the most innovative solutions for automated logistics processes one could conclude that pallet handling should be eliminated from the warehouse management. They should be replaced by automated miniload systems designed for packages of smaller sizes that are transported and stored automatically without the necessity of using pallets and lift trucks. "Eliminating unnecessary processes has many advantages such as speeding up the material flow and positive effects on the environment, e.g. the elimination of pallets and shrink wrap foils necessary for palletized goods. And I must admit that another reason for our decision was the 40% investment subsidy from the Innovative Economy Program, Activity 4.4", adds Gnych.

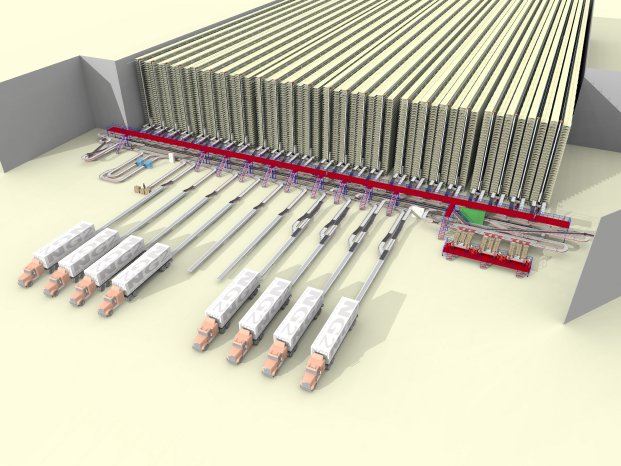

TGW's concept is based on the direct storage and handling of individual cartons throughout the installation, from goods receiving to the shipping zone. At goods receiving the cartons are placed on the conveyor system, identified and checked. Then they are stored in a fully automated carton warehouse. In comparison to most of traditional approaches this solution allows for avoiding the now unnecessary process of palletizing the goods and storing them manually in pallet racks. It reduces both time and distance for the workers and minimizes mistakes that might occur each time a product is touched. The automated storage and retrieval system (AS/RS) supplies all other warehouse zones such as picking, sorting and dispatch - fully automatic and always on time.

How will it work for NG2? Imagine a huge warehouse where 30 containers filled with shoes arrive every day. The truck with the container approaches the designated dock, the doors of the container are opened and a telescopic conveyor is moved into the container onto which the workers unload the cartons. Each carton receives an identification label with a barcode; its weight gets checked and is registered in the system. Reaching the conveyor loop the cartons go through a control gate which precisely measures their outside dimensions. In case of any inaccuracy the carton is transported to a control station.

After passing the control gate the cartons are automatically stored in the warehouse which is operated by stacker cranes. The warehouse management system decides where the carton is stored. Each of the 24 cranes can store and retrieve two cartons at the same time. Thanks to the Twister VCplus load handling device it is able to operate with cartons of very different sizes.

The host system sends the required orders to the warehouse management system. Then the requirement is sent to the order buffer, where it is released immediately. Destination of such an order may be the shipping zone or the sorting installation, where individual pairs of shoes are sorted. The cartons which are transported directly to the shipping zone receive a shipping label and end their route on a telescopic belt conveyor at the door of the trucks. This is the second and the last time the worker has to touch the goods.

The heart of the system will be a miniload AS/RS which will contain 5 million pairs of shoes, packed in 500,000 cartons of different sizes, ranging from 400 x 400 x 200 mm to a maximum size of 660 x 610 x 550 mm.

In combination with the existing sorting solution, the new distribution centre will be able to handle up to 60,000 cartons per day in two working shifts. This means that NG2 will possess the biggest automatic miniload warehouse in this part of Europe.

After implementing the new system the capabilities of NG2's distribution centre will change drastically. Investments are the key factor in the company's development strategy. "The warehouse inventory exceeds 5 million pairs of shoes and in combination with existing sorting system we can deliver up to 0.5 million pairs of shoes per day. Furthermore, the solution will be integrated into the company's ERP system. The joint efforts of TGW and NG2 will make this project a full success", summarizes Mariusz Gnych.

www.tgw-group.com

Equipment installed at the NG2 distribution centre:

- 24 miniload warehouse aisles equipped with 19.5 meter high Magito AS/RS machines with Twister VCplus load handling devices for directly storing and retrieving 500,000 cartons

- extensive carton conveyor system connecting the various processes within the distribution centre

- ergonomic working stations

- telescopic conveyors for container loading and unloading

- fully integrated software system CI_LOG including interfaces for higher levels of the warehouse management system