- Digitization and Industry 4.0 are key for thyssenkrupp's aim of enhancing urban mobility and making cities the best ever places to live

- The Internet of Things (IoT) enables a dramatic increase of elevators availability

- Intelligent and connected MAX elevators raise safety and reliability to new levels

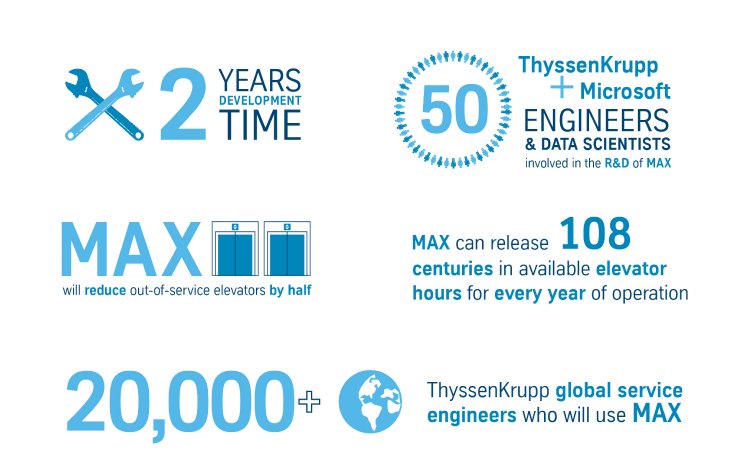

Using Microsoft Azure Machine Learning, thyssenkrupp has succeeded in establishing a completely new preventive maintenance system; instead of reacting to problems, service engineers can now access real-time data and take proactive measures to prevent elevator breakdowns before they occur. With the groundbreaking MAX installed worldwide, time savings for elevator passengers could be equivalent to 95 million hours in each year of operation.

"Integrated Industry - Discover Solutions” is this year’s lead theme at Hannover Messe 2016. A perfect match to showcase the company’s latest innovation, which leverages the power of IoT to enhance the efficiency and availability of the world’s most widely used means of passenger transportation.

As thyssenkrupp Elevator CEO Andreas Schierenbeck stated: “Together with Microsoft, we are digitizing our industrial products and turning Big Data into smart data. Through this, we are extending our business model and thus securing a significant competitive edge.” He added, “MAX will enable us to offer customers predictive and even preventive service for their elevators, striving to enhance urban mobility and make cities the best ever places to live.”

MAX and its impact on the elevator industry will be showcased at the Microsoft booth, Hall 7, Stand C40 from April 25 to 29, 2016 at the Hannover Messe.