High standards in the aerospace industry

Even policymakers agree that the aerospace industry has a strategic role to play. In fact, hardly any other market is so pioneering when it comes to the use of innovative materials and processes. This is why R&D expenditure in this field, which is already double that found in other industries, is set to continue increasing for years to come. "Completely reproducible processes with full traceability are essential wherever people's lives depend on the operational safety of end products," explains Christoph Hauck, who is a managing director of toolcraft and is responsible for 3D metal printing. "To ensure that these requirements are met, suppliers are subject to strict quality standards." Nadcap certification was launched in 1990 to avoid the costly and time-consuming need for individual assessments, which often actually resulted in the same inspections being performed twice. Developed by major aerospace companies, the programme defines a common standard.

Establishment of a common standard

The Performance Review Institute (PRI) has been responsible for administering the certification process from the outset. The universally accepted certification confirms that a company fulfils strict aerospace industry standards. The pooling of expert knowledge means that the programme provides an audit that is far superior to any individual inspection. It therefore improves supply chain quality, while simultaneously making processes more efficient for clients and suppliers. The Nadcap Management Council consists of senior quality leaders and managers from the key contractors and suppliers in the aerospace industry.

Nadcap certification

Certification to EN 9100 is a prerequisite for Nadcap accreditation and ensures that the company meets the aviation-specific additional requirements needed for ISO 9001. The criteria for additive manufacturing in metal-powder bed procedures using lasers and electron beams comprise requirements concerning materials management, equipment, the process itself, the qualifications of personnel, and plant and equipment maintenance. Materials management covers everything from procurement and storage to handling and recycling. During the inspection of equipment, emphasis is placed on the testing of process variables, software (including regular updates) and the upkeep of facilities. Attention is also given to the individual process steps. The manufacturing process is also inspected in terms of the method taken when changing the powder and the procedure followed in the event of system errors. From now on, this inspection will take place in line with Nadcap specifications at regular intervals, enabling the stringent standards to continue to be met in the future.

Additional certifications

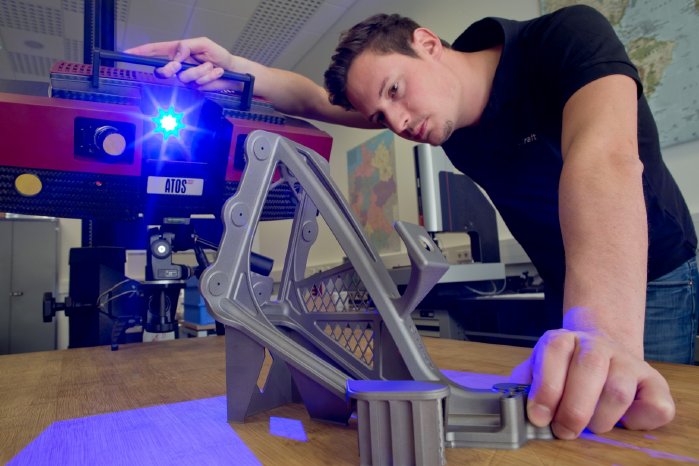

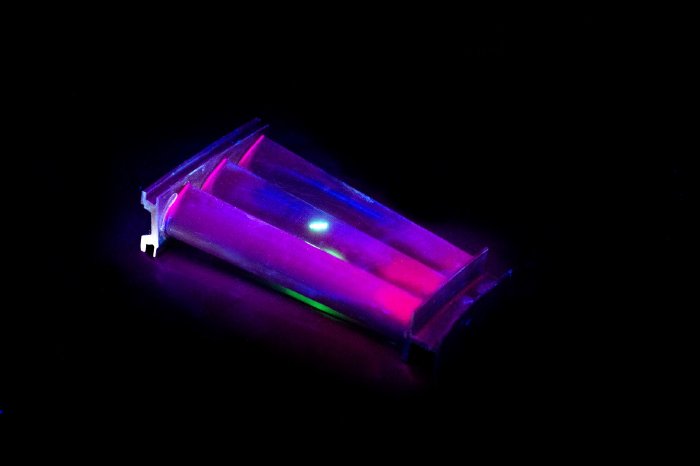

toolcraft is also DIN 2303 certified. This certification is required by companies that use thermal joining processes (welding/brazing/thermal spraying) when manufacturing or repairing military products. DIN 2303 certification is required for components belonging to the classes BK1 to BK3, is granted differently depending on the component class and always takes the materials into consideration. toolcraft works continuously to improve its processes and its entire process chain, including the performance of optical and tactile measurements and non-destructive testing, which also meets the requirements of Nadcap. The company also evaluates the dynamic strength of various metals using fatigue testing performed in its own lab.