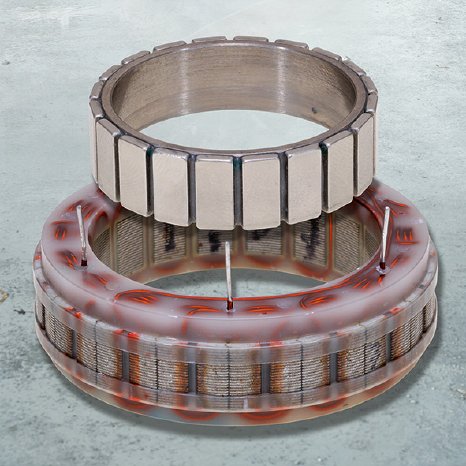

RoboDrive technology, developed by researchers at the Institute of Robotics and Mechatronics of the German Aerospace Center (DLR), combines high torque development and power density relative to weight and installation space. Factors like synchronization, dynamics, and thermal connection are also geared towards the particularly high requirements of robotics.

TQ has manufactured these engines since 2006. The new TQ drive engineering business division now provides users with a broad spectrum of solutions and specific expertise in integration problems with the help of RoboDrive technology. The term "embedded drives" describes the close connection between the overall system and the drive components.

Many other applications apart from robotics benefit from the properties of RoboDrive technology. Shorter cycle times and lower winding temperatures can be achieved in positioning tasks where the overall efficiency is always zero. Battery working times last longer for an increasing number of network-independent applications thanks to minimized losses in engines. In the automotive area, more compact electric drives can take on a greater variety of tasks. In the semi-conductor industry and in optical applications, high-precision regulations permit accuracy to within the thousandth part due to optimized bandwidth. In medical applications, the smallest instruments can be run on electric drives and lower, body-compatible temperatures reached for implants. In machine tools, power densities that previously required hydraulic drives can be achieved in the smallest installation spaces.

TQ at electronica: hall A6, booth 307

TQ at SPS/IPC/Drives: hall 1, booth 151