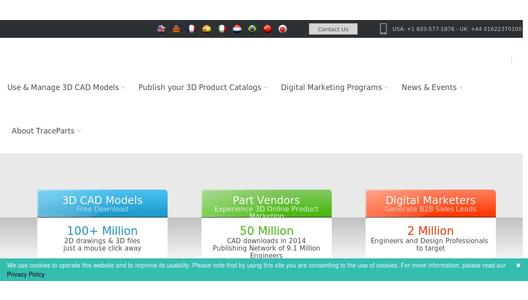

Just like open-access CAD content, which has been widely available for the last 15 or so years, 3D printing is on the verge of revolutionizing the industrial parts market. For industrial design professionals, minimizing the development cycle for new products is a top priority. With an engineering platform such as TracePartsOnline.net, they can now identify, view and download the part that they need for their design project in the CAD format of their choosing.

However, the final stage of validating their design project, which involves producing models or prototypes, raises certain challenges. This is where 3D printing really comes into its own.

To date, design professionals have only had one solution for producing their prototypes, namely reaching out to manufacturers or vendors, requesting samples and waiting for delivery before getting started on assembling the prototype. Thanks to 3D printing, they can now freely download the CAD models for each part in STL format (STereoLithography) and begin printing.

Parts suppliers can save precious time for their customers with 3D printing, while significantly reining in the costs associated with storage, administration, obsolescence and delivery from their stock of samples.

"Our manufacturer and distributor customers are constantly wondering how they can deliver superior quality of service to engineering and design firms, while streamlining operating costs. Our download solution, which is compatible with 3D printing and accessible from our TracePartsOnline.net industrial parts library, means that they can build a win-win strategy with specifiers", concludes Christian Baumgärtner, Managing Director of TraceParts GmbH.