So that the appropriate laser is available for each application, TRUMPF is offering fiber lasers in addition to disk, diode, rod and CO2 lasers. Customers can use these for applications in the multi-kilowatt range, in precision processing, in micro processing or for laser marking. "Because we are a one-stop shop for beam guidance, processing optic, and control and automation elements, the customer can be confident that all components are completely compatible with one another," Leibinger emphasizes.

Application centers pool laser expertise

Although the laser's range of applications as a tool in materials processing is universal, the road to using it in integrated application solutions is highly individual. The work piece to be processed, the specific application, material strength, accuracy, batch size, version variety, reproducibility, type of material, material flow and the costs of parts - these are all criteria that have to be thoroughly discussed with the customer to find the best and most cost-effective solution.

To give users the best possible support in selecting the appropriate laser beam source, TRUMPF has consolidated at its application centers around the world its experience and expertise gained from developing beam sources along with decades of experience in applications and laser integration. Here, customers will get the help they need to identify the right laser beam sources and to optimally align production systems with one another. "Based on our long-term experience with the laser in materials processing, we have comprehensive application expertise from many different industries that allows us to work out the best solution for our customers," says Leibinger. "Depending on how our customers respond to different questions, for some the CO2 laser is the tool of choice, for others, it's a solid-state laser. Each technology brings with it its own particular advantages that can be specifically leveraged."

Product lines to be exhibited at the LASER trade show:

TruFlow. Over many years, flow CO2 lasers have become well established in laser materials processing as reliable and robust beam sources. Tens of thousands of beam sources worldwide have proven reliable as universal cutting and welding tools.

TruCoax. Diffusion-cooled CO2 lasers are impressive due to their compact and lightweight design. And with a high beam quality, they are optimal for thin sheet processing.

TruDisk. With laser outputs of up to 16 kilowatts and beam qualities starting at 2 mm*mrad, disk lasers offer unrivaled robustness - for highly productive thin sheet cutting as well as for welding.

TruDiode. With a socket output efficiency of up to 40 percent, diode direct lasers are extremely energy efficient and particularly well suited for welding applications.

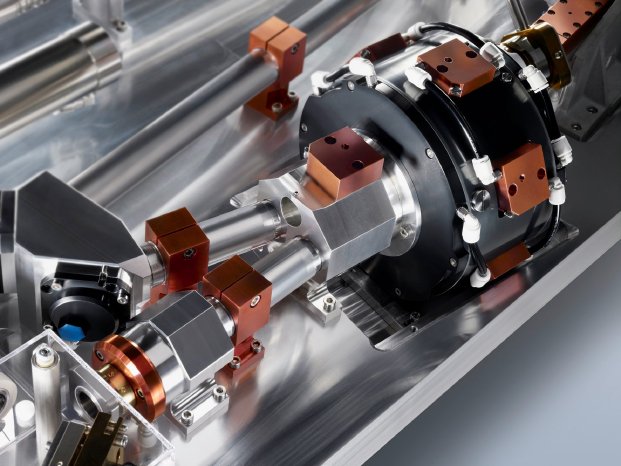

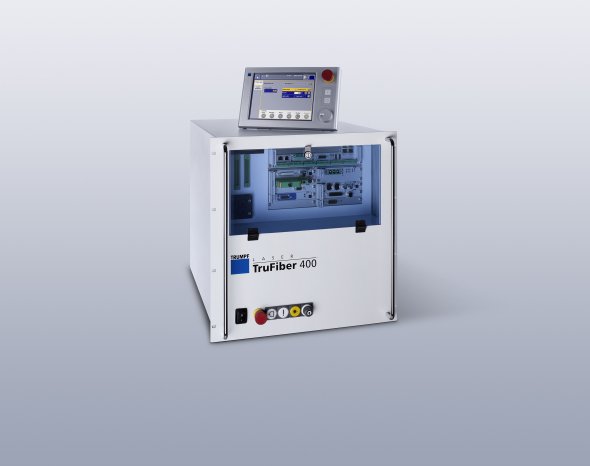

TruFiber. Fiber lasers are impressive due to their high processing speeds in the lower output range. With laser outputs between 200 and 400 watts in basic mode beam quality, they are ideal for precision processing.

TruPulse. With short high-energy pulses at a higher pulse output, pulsed solid-state lasers are ideal for spot or seam welding as well as cutting, boring and material removal.

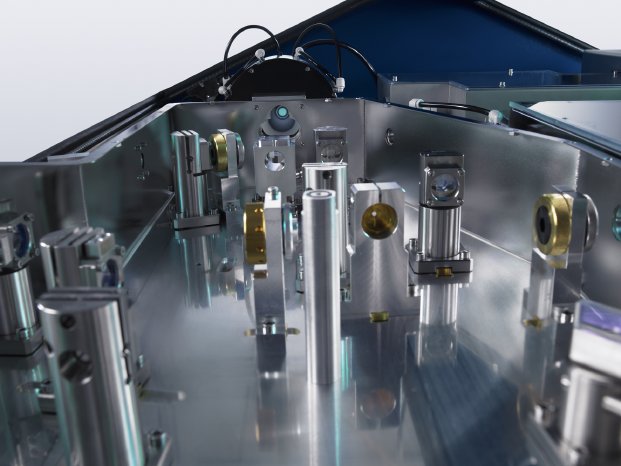

TruMicro. Short and ultra-short solid-state lasers are being successfully used in micro production and photovoltaics for structuring, material removal, edge stripping, cutting or boring.

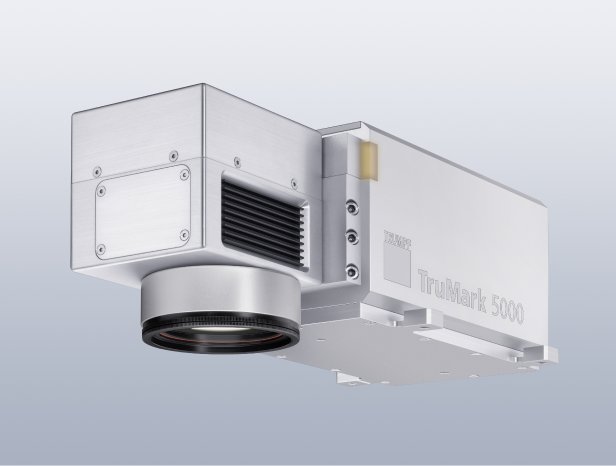

TruMark. With beam sources in all relevant wavelengths (infrared, green, ultra-violet), marking lasers mark metals, plastics, glass, ceramics or organic materials - at a high quality level that lasts.

TRUMPF at LASER WORLD of PHOTONICS, May 23 to 26, 2011, Munich Exhibition Grounds, Hall C2, Booth 341