181 zettabytes or, in other words, the number 181 followed by 21 zeros – this is the prediction for the amount of digital data generated worldwide by the year 2025. How can this gigantic amount of data be transferred in a quick and stable manner? Copper cables alone cannot cope with this volume. The solution is light, namely via fibre optic cables.

Many advantages of fibre optic cables

Fibre optic cables transport large amounts of data at up to 40 Gbit/s over different wavelengths simultaneously and are resistant to electromagnetic interference. As a result, there is no signal interference and no data loss. Furthermore, considerably longer installation lengths are possible than for copper. Copper cables are designed for a maximum of 1000 metres at 10 Mbits/s (single-pair Ethernet). Glass fibre cables, on the other hand, can easily achieve 40 Gbit/s over 40 km at 1550 nm. This enables synchronised real-time capability and therefore efficient production through fast communication, even at very high data transmission rates such as the “digital twin”, robot AI and Industry 4.0. What's more, there are large space savings due to the smaller diameter and weight of the cable.

Innovative pluggable glass fibre connection

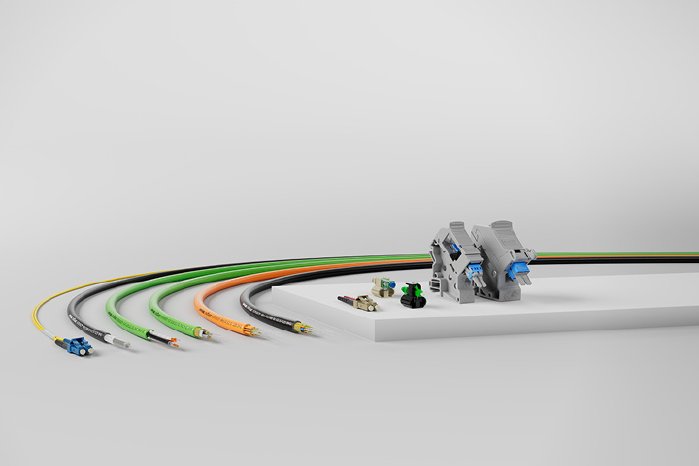

In order to simplify the establishment of a pluggable glass fibre connection, LAPP, the global market leader for integrated solutions in the field of cable and connection technology, has launched the new site-assembly EPIC® DATA FFC-LC connector (in accordance with DIN EN IEC 61754-20) and EPIC® DATA FFC-SC connector (in accordance with DIN EN IEC 61754-4) for GOF fibre optic cables. They are available for different fibre categories (OM3/OM4 and OS2), polish types (APC, UPC or PC) and variants. The Lucent Connector (LC) and Subscriber Connector (SC) feature a Fibre Fast Connect (FFC) system, which enables GOF fibre optic cables to be assembled easily, quickly and flexibly – even in tight spaces. Thanks to a refraction index gel, constant and excellent optical values are guaranteed. Special tools, laboratory conditions and time-consuming process steps are no longer necessary.

The site-assembly LC and SC connectors are practical too. They are prepared and tested at the factory so they are ready for on-site assembly. Serial numbers on the individual connectors ensure complete traceability. The connectors can also be assembled up to 3 times. Typical areas of application are backbone networks, cabling of buildings and data centres or use in control cabinets. The connectors are available as a set in the cable variant (diameter 2 or 3 mm) or core variant (diameter 0.25 or 0.90 mm). This makes it far easier to establish a pluggable glass fibre connection.

Complete package of add-ons

In line with the motto of “everything from a single source”, LAPP also provides customers with an entire package to make assembly on site easier.

- The EPIC® DATA FFC-LC and EPIC® DATA FFC-SC assembly accessories are virtually emergency stock in case the corresponding accessories run out. This includes a cable assembly set for secure insertion of the glass fibre into the connector and for simplified attachment of the strain relief by fastening the aramide fibres on the side. Cable clips for fixing cables with a diameter of 2 or 3 mm, as well as a fibre guide for secure insertion of the glass fibre into the connector and for attachment of the strain relief by manually fastening the aramide fibres.

- In addition, there is an EPIC® DATA FFC-LC- and an EPIC® DATA FFC-SC starter kit as basic equipment with site-assembly Fibre Fast Connect LC and SC connectors, fibre separator and fibre guide. The highly precise fibre separator (cleaver) serves to shorten the glass fibres by means of a straight polish (PC/UPC) or angled polish (APC). This achieves ideal return loss values. The cleaver can be used up to 200 times and has a mechanical, visually readable counter. The user needs the fibre clamp to hold the core. It prevents the glass fibre from being pulled back. A red marking on the fibre clamp helps for an exact offset of the glass fibre. Of course, the starter kit is available for the different polish types (APC, UPC or PC) and the GOF fibre categories (OM3/OM4 and OS2), but also as a set in the cable variant (diameter of 2 or 3 mm) or core variant (diameter of 0.25 or 0.90 mm).

- As a third add-on, LAPP has the HITRONIC® FO toolkit in its portfolio. This is a complete tool kit for preparing GOF fibre optic cables and connectors, fully equipped with all necessary tools and cleaning agents and other accessories. The kit includes, for example, aramide scissors with special cutting edge for easy cutting of aramide fibres. A compact red light source with clearly visible light for continuity testing of fibre optic cables and for optical break or fault identification. Fibre stripping pliers with a die for common diameters for stripping the individual layers of the fibres. Furthermore, the tool kit is also equipped with lint-free cleaning wipes and cleaning liquid, tweezers and a container for fibre residues, two ferrule cleaners, and a practical cleaning cartridge for removing dirt from the connector ends.