The principle behind the e-joint is that the oil, which is necessary in the use of e-joints, is extracted using a specific preparation of the cannabinoids. The oil contains over 40 % tetrahydrocannabinol, otherwise known as THC, and through this special preparation a much higher concentration of the plant substance can be extracted compared to that found in joints.

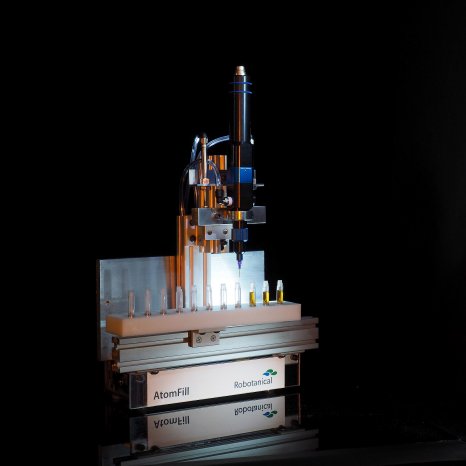

Since the beginning of its production, the eco-PEN600 has been used for the dosing of oil in the filling lines of the e-joint. The requirements of the customer are to dispense exactly 3 grams of oil into an e-joint and to produce as little waste of the high quality cannabis oil as possible. These requirements can be achieved due to the high repeatability of ˃ 99 % and without being dependent upon pressure, time or temperature. In addition, wear and tear of the stator is reduced due to the good lubrication properties of the oil and therefore maintenance costs are also significantly reduced.

Demand for the e-joint has been increasing steadily since its launch and currently 10,000 units are being produced on a daily basis. The introduction of more filling lines is already being discussed.