Dosing and delivering micro doses is a breeze for the VHD. “It impresses not only with its outstanding hygienic standards, which come close to those of the pharmaceutical industry,” explains Wolfgang Merklein, Head of Food & Cosmetics at ViscoTec, “but also through the ease with which it can be implemented on production lines with regard to dosing small quantities in the production of food and cosmetics. With VHD in our portfolio, we couldn't be better equipped for Industry 4.0 and individualisation concepts such as customised food.”

The new dispenser is even capable of delivering or applying difficult high-viscosity liquids with aplomb. Decorative finishes with icing or chocolate or even the delivery of complex cosmetic products can be achieved with simple process steps.

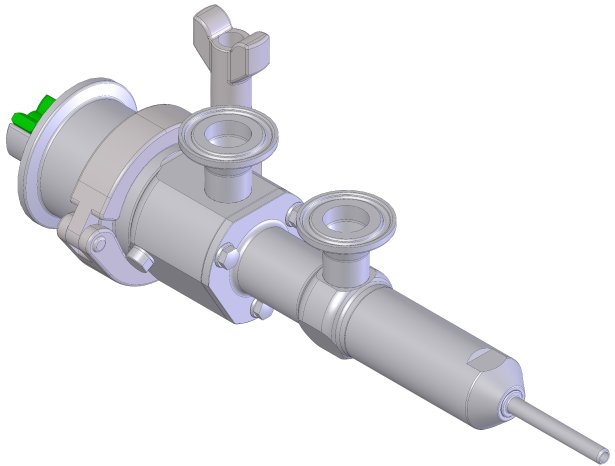

Entirely new possible uses and ranges of applications which were until now limited in the food and cosmetics industry are becoming reality. The benefits of the endless piston principle (adjustable suckback, for example, which guarantees clean dosing and maximum precision) can be used for the very first time in all manner of delivery and dosing applications in the field of hygiene and aseptics.

Together with the ViscoTec products for the food and pharmaceutical sectors, which have earned a reputation for reliability (equipment for emptying vessels and the Pharma Dispenser, for example), the “newbie” is closing the gap and also offers ideal options for dosing in the food and cosmetics sectors.

ViscoTec pump and dosing technology at FachPack 2016 ̶ Hall 3A, Stand 206.