The thermal pastes are usually high-filled substances, so called 'Gap Fillers'. The correct dosing is especially important here. The layer thicknesses have to fit in a special defined tolerance field. On top of that there are the high costs for these materials - that's why highly accurate dosing technology is mandatory for applications like this.

Therefor the preeflow® eco-PEN/eco-DUO, made by ViscoTec, offer optimal dosing characteristics. With this one- and two-component dispensers we speak about a rotating, absolutely pressure-tight, positive displacement system with self-sealing rotor-stator arrangement. The controlled rotary motion of the rotor transfers the medium by displacement in the stator. The medium is unchanged by this process. Due to the applied endless piston principle the dosing happens purely volumetric and pulsation-free.

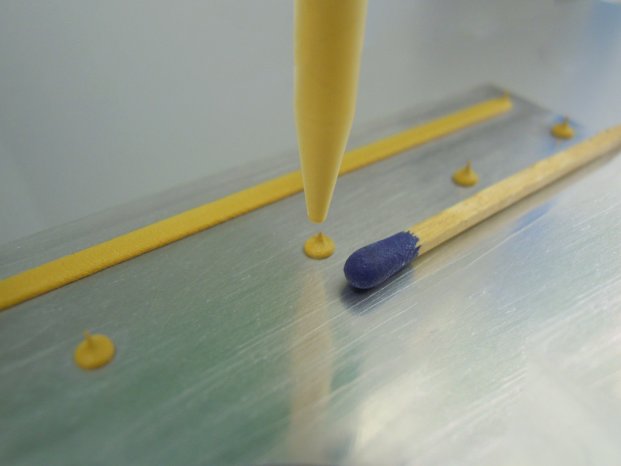

And simply by switching to reverse-flow, preeflow® ensures a clean and controlled stop of material or medium. No drips, no mess! Specialties of this precision-volume dosing unit are on-the-dot dosage with maximum volumetric precision, dot-and-bead application with application speeds adaptable to track speeds and joint sealing technology.

Viscosity-independent dosing, easy cleaning, EDI (Easy Dispensing Integration of the preeflow components into semi and fully automated processes), range of dosing pressures up to max. 40 bar without additional valve technology and many other special features ensure the consistent quality and the reliable workflow. Not without a reason the dispensers by ViscoTec stand for "micro-dispensing in perfection!" as well as in the one- and the two-component application market.

You can find further information about our products on our website www.preeflow.com or here: https://www.youtube.com/...