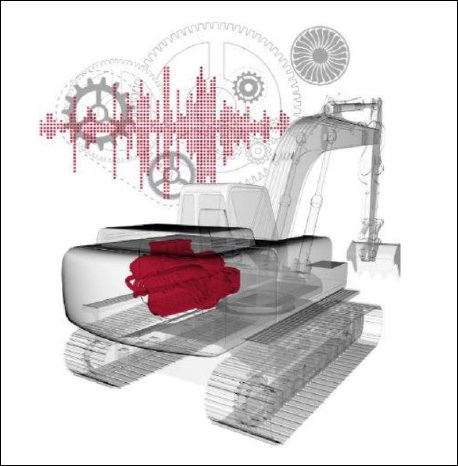

Following on from cars, the EU Commission wants to significantly reduce CO2 emissions of heavy-duty vehicles such as construction, forestry and aggricultural vehicles. In 2030, this should be at least 30 percent below the 2019 level and fall by 15 percent by 2025. In addition to optimizing fuel consumption, development engineers are also focusing on the durability of powertrains. Torsional vibrations in the powertrain lead to increased wear and tear and pollutant emissions. In order to reduce these, high demands are placed on precise measurement and analysis technology.

The modular Rotec measuring system, which has been tried and tested in the automotive sector for more than 30 years, guarantees high-precision measurements of torsional vibrations in drive trains. On the basis of the Rotec speed channels with 12.3GHz clock frequency, extensive analysis of the drive train and the auxiliary drives can also be carried out with the aid of the various optional measuring cards, such as analog measuring cards with 50kHz and 3.2MHz sampling rates or the strain gauge measuring card for piezo-resistive, magnetoresistive or potentiometric transducers. Typical applications in the construction, forestry and agricultural machinery sectors are the analysis of torsional vibrations of the crankshaft, the tuning of torsion dampers, the optimization of valve drives (in towed or fired operation), clutches, transmissions as well as chain and belt drive systems.