Ideal tool for research

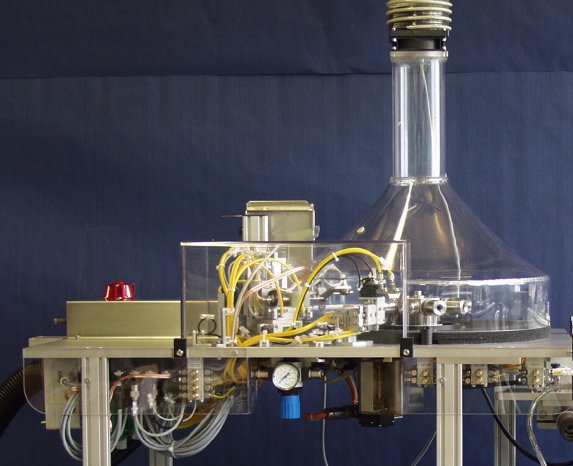

The smoking robot VC 10 is used for product analysis or when a standard aerosol is required for an in vitro test with cell cultures. For this purpose human cells are cultivated on membrane inserts in special VITROCELL® cultivation and exposure modules. Then the cells are exposed at the air/liquid interface to the test substances. For the direct exposure to bacteria (Ames Test), a special module for Petri dishes is used.

Freely programmable parameters

The computer system of the smoking robot allows highly flexible programming of the smoking process. Changing from single cigarette smoke to serial smoke mode for a defined number of cigarettes is possible. All parameters of the smoking process can be defined according to the needs of the experiment:

> puff and exhaust duration

> puff frequency

> puff volume

> puff profile

> ventilation flow rate

> butt length sensor

> single smoke (1 cigarette) or

> serial smoke (1-10 cigarettes) mode

Generation of smoke with the shortest distance to the analytical instrument

The success of an experiment with mainstream tobacco smoke it is important that the distance between the smoke generation (cigarette holders) and the analytical instrument is as short as possible in order to avoid aging and to guarantee a smoke composition matching the real-life situation.

Open and flexible system / integration of other analytical tools

The robot is designed to allow easy access to all tubes, filters and the pumping system. The feature is very important when working with whole smoke. The mainstream smoke requires easy access to all components for cleaning purposes. Additional analytical equipment relevant to the experiment can be installed without difficulty.

VITROCELL® SYSTEMS offers a large product program of equipment for the in vitro analysis of airborne substances such as gases, nano particles and complex mixtures. The VITROCELL® product range helps to reduce animal testing in the field of e. g. inhalation toxicology. For this purpose human cells are cultivated in special exposure modules on membranes and then exposed at the air/liquid interface to the test substances. The customers of VITROCELL® are leading medical and environmental research institutes as well as the pharmaceutical and other industries.

More information:

Tobias Krebs

Phone: +49 172 60 40 370

www. vitrocell.com

info@vitrocell.com