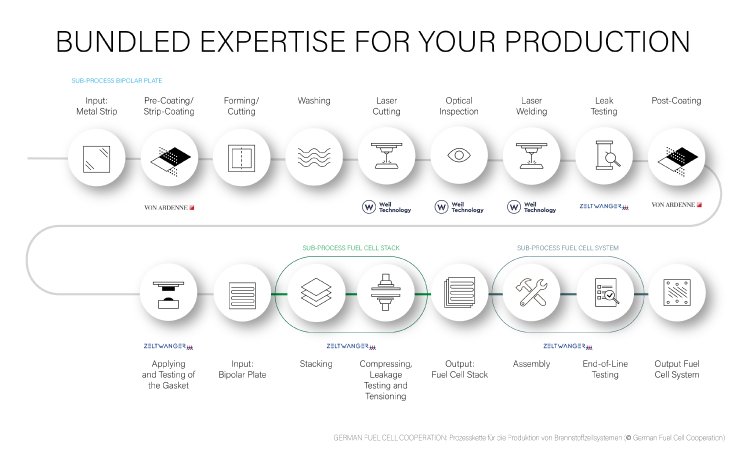

By combining their respective competencies, the three companies VON ARDENNE (Dresden), Weil Technology (Müllheim) and ZELTWANGER (Tübingen), as partners in the GFC, offer manufacturers of fuel cell systems and electrolyzers fully comprehensive know-how for the efficient production of metallic bipolar plates.

The concept of a fully coordinated production line plays a pioneering role in the market. And, with an annual production capacity of several million bipolar plates, it serves the current needs of the industry.

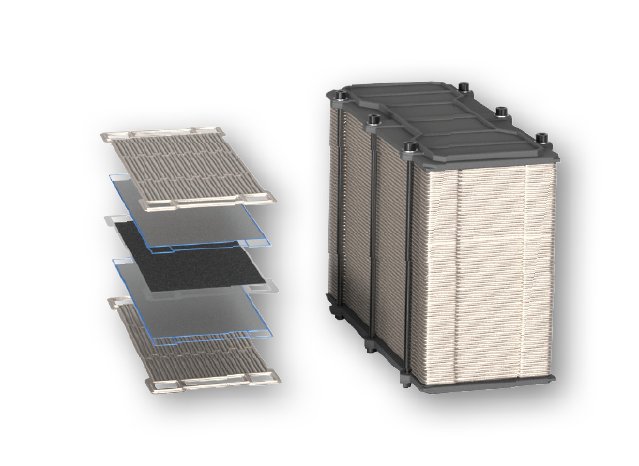

The long-standing expertise of the three mechanical engineering companies covers all process steps. And the joint development and careful coordination of the line concept enables smooth transitions at the interfaces of the individual production steps. To this end, the line processes pre-stamped half-plates made of stainless steel or titanium. In a first step, these are welded into bipolar plates, then leak-tested and given a PVD coating to functionalize the surface.

With their extensive joint knowledge of the complex value chain and high degree of specialization in the subprocesses, the three GFC companies develop a customized production line together with their customers. These specification-compliant production lines optimally integrate the various customer-specific approaches.

VON ARDENNE contributes its expertise in the construction of vacuum coating systems used to functionalize surfaces of metal strip (pre-coating) or bipolar plates (post-coating). Weil Technology is an experienced supplier of equipment in the field of laser cutting and laser welding of metallic bipolar plates. ZELTWANGER provides the equipment for automated assembly and testing processes as well as leak testing into the production chain.

Conference papers and presentations of the GFC at the F-Cell

Conference presentation at the f-cell conference

DATE: Tuesday, 4 October 2022, 2:30-3:30 p.m.

One of the four experts in the topic window

"Automation and manufacturing technology for fuel cell production."

Florian Weil, Division Manager Development & Innovation, Weil Technology GmbH:

"German Fuel Cell Cooperation: success factor for fuel cell production".

Presentations in the f-Cell Speaker Corner

DATE: Wednesday, 5 October 2022

11:30-11:40 a.m.

"Laser welding of metallic bipolar plates: robust, modular and scalable"

Harald Liebhart, Weil Technology GmbH

11:40-11:50 a.m.

"From Lab to Fab: Scalable thin-film coating solutions for bipolar plates"

Susann Puppe, VON ARDENNE GmbH

11:50-12:00 a.m.

"Ensuring leak tightness of fuel cells and electrolyzers"

Patrick Reich, ZELTWANGER Group

GERMAN FUEL CELL COOPERATION – Booth and Contact

DATE: 4. - 5. Oktober 2022

BOOTH: Halle 2 / 2D17

WEB: www.fuel-cell-cooperation.com | www.f-cell.de

THE COMPANIES OF THE GERMAN FUEL CELL COOPERATION

About VON ARDENNE

VON ARDENNE develops and manufactures systems for the industrial vacuum coating of materials, such as glass, wafers, metal strips or polymer films. Depending on the application, these coatings are one nanometer to a few micrometers thin and give the materials new functional properties. Our customers use these materials to produce high quality products, such as solar cells and solar modules, architectural glass and vehicle glazing, fuel cells, lithium ion batteries or microelectronic components for sensor systems and optics. Systems and components provided by VON ARDENNE make an important contribution to protecting our environment. They are crucial when producing products that help to consume less energy or that generate energy from renewable resources.

With more than 60 years of experience in electron beam technology and over 45 years of experience in magnetron sputtering, VON ARDENNE is a pioneer and worldwide leading supplier of systems and technologies in PVD thin-film and vacuum process technology. We offer our customers technologically mature vacuum coating systems, comprehensive expertise and global service. The key components are developed and manufactured in-house at VON ARDENNE.

About Weil Technology

As a machine builder and solution provider, Weil Technology helps to implement new production processes in sheet metal processing and to optimize, automate and make more sustainable existing sheet metal processing.

The company's core expertise is machines for sheet metal processing via laser welding and laser cutting. Weil Technology can look back on over 30 years of experience here. At the company head office in Müllheim in Bavaria, approximately 220 employees develop and produce custom concepts and systems.

About ZELTWANGER

The companies of the ZELTWANGER group are among the technology and innovation leaders in the development and manufacture of modern systems for automation, leak testing, laser applications and thermal management.

In the e-mobility industry, ZELTWANGER offers various solutions along the entire value-added chain for the production and quality assurance of battery systems, fuel cells and electric motors.

The modular devices and systems for the sealing and functional testing can easily be expanded by using plug-and-play measurement modules, which is unique on the market in this form.

Moreover, ZELTWANGER develops and realizes high-end automation systems, such as stacking systems for the fuel cell industry.