Therefore the electrical Pitch System developed by W2E Wind to Energy fundamentally differs from the conversional technology. The modularity, die dimensioning, the choice of parameters, the circuitry technology, the safety system and the installation were designed, that a safe, sturdy and simple solution was reached at the same time.

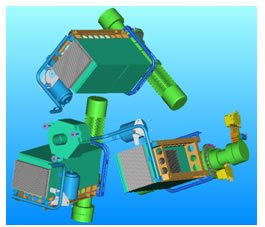

The plug & play concept means, that all three axes of the Pitch System use identical switch-gears. There is no central controller inside the hub. Therefore the triple independency is consistently given. All cables are double-sided finished with plugs of the company HARTING. These plugs of the type HPR ensure the protection class IP68 and a very high level with regard to EMC. The concept is capable for sufficient tests of all components by the supplier and a faultless assembly.

W2E has developed a new backup for Pitch System applications in cooperation with the companies HARTING und GAIA. Lithium-ion-accumulators ensure a stable, ten years maintenance-free operation, as well as high safety margins and availability. These accumulators are able to supply and draw very high current like capacitors. Also, this capability is maintained at low temperatures. The device contains 24 Lithium-Ion-Accumulators incl. a battery man-agement system. Alternatively in all W2E Pitch Systems the use of capacitors is possible without any change of circuitry, software and parameters. The German Patent Office issued a Registered Design for the novel circuitry and for the procedure. A European patent applica-tion has been prepared.

The lithium-ion-accumulators are arranged at the DC-link between a pulsed rectifier and the inverter. Therefore the Pitch System does not include a brake chopper, a battery charger, or power switches, which have to be used in case of grid failure. In principal, detection of the so called Fault Ride Through according to the grid code “High and extra high voltage” of the e.on Netz GmbH, is not required.

The motor works with specific lower speed to reduce swash losses of the planetary gear. Powerful and sturdy inverters supply a higher maximum torque. All smart pitch functions are included in an industrial-suited PLC, which works independently from the operating system. A new procedure is able to prevent overspeed events and the typical load-generating luff tilting of the tower head during fast pitch braking. W2E has mastered the complex control-loop procedures of individual blade pitch. The procedures promise to reduce fatigue loads by 20 - 25% and take the edge off extreme loads.