In steel mills and cement plants, but also in power stations and in the entire chemical industry, special requirements are imposed on assembly pastes. Extreme temperatures as well as aggressive chemicals, alkalis and acids require special product properties.

Extremely resistant

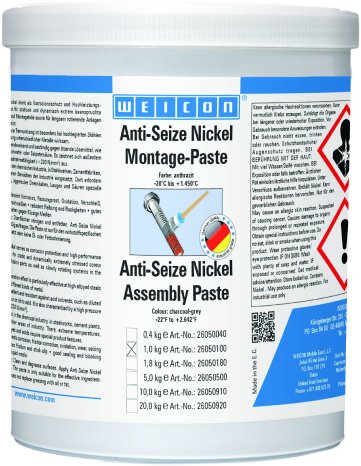

Anti-Seize Nickel has been developed to resist this extreme conditions and to match the high requirements. It is highly sticky, water repellent and resistant to sweet, salt and hot water as well as steam. The high amount of nickel component furthermore provides protection against corroding and corrosive solvents which are contained in diluted hydrochloric acid, sulphur or nitric acid, among others. Anti-Seize Nickel can be applied at a wide temperature range between -30°C (-22°F) to +1,450°C (+2,642°F).

It serves as corrosion protection and high-performance assembly paste for static and dynamically extremely stressed screw connections and installation parts. The paste is suitable for the application at slowly rotating systems in the high-temperature range.

Anti-Seize Nickel protects against corrosion, seizing, wear, stick-slip effects, oxidation and friction corrosion as well as electrolytic reactions, the so-called cold-sealing.

Anti-Seize Nickel contains selected additives as well as special solid lubricants in the smallest particle size. These lubricants guarantee the special product characteristics. The very good separation effect is particularly effective with high-alloy steels as well as on different metals.

Suitable almost anywhere

Anti-Seize Nickel is used to solve basic problems and is not bound to any industry. Corrosion, seizure and wear are typical damages that can occur in almost all industrial areas.

It can, for example, be used on seals, valves, screw connections, gear wheels, bearings, jets, conveyor belts, stud bolts, tools or cylinders.

Anti-Seize

A safe protection of workpieces and constructions made of steel and other metals is very important for the rational and economic operation of technical installations.

Anti-Seize assembly pastes have been specially developed for these kind of requirements. They serve as protection, separation and lubricants for highly stressed parts - in particular at high temperatures. Ideal matched solids and selected additives allow a wide range of applications in almost all areas of industry.