– expansion of the terminal block portfolio of the A-Series with new installation terminals

– digital design in the Weidmüller Configurator WMC

– wide range of functions

– ready to robot

– combination of different connection systems

– clearly distinguishable functional areas

– safe isolation of the neutral conductor for insulation measurement optionally via standard disconnectors or disconnect sliders.

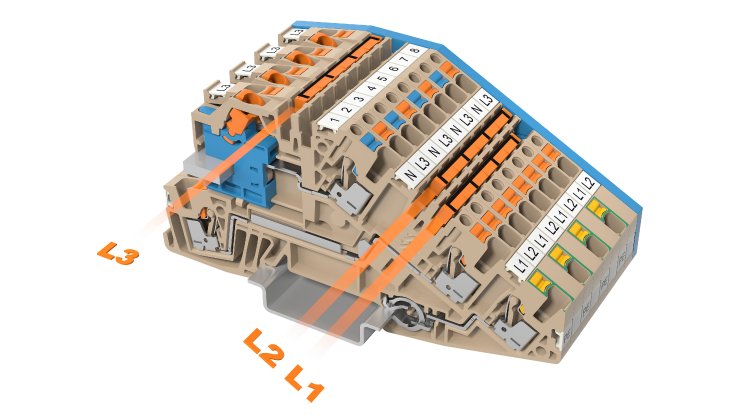

The requirements for building installations are manifold: Energy efficiency and safety are among them, as are flexibility and convenience, to name only the most important. The necessary infrastructure in a building requires numerous main, sub-distribution and small distribution boards as well as meter cabinets. What they all have in common is that they must accommodate very many functions in a very limited space. From planning and installation to operation and maintenance, this requires first-class installation solutions that ensure clarity and ease of service in every installation situation. For this purpose, Weidmüller has developed the new A-Series AITB installation terminals, which meet the wiring and connection requirements in installation distributors according to VDE. With the new terminal block systems, the multiplication of potentials in a 3-phase system can be easily realised via cross-connections.

Practical connection system across all cross-sections

The new terminal block systems are equipped for every task. The uniform busbar position even makes it possible to combine different terminal block products and connection systems in one overall system. For large cross-sections – e.g. N conductors – the side screw terminal connection is available. Terminal blocks with convenient PUSH IN connection systems are used to collect and distribute the potentials. With this, even stranded wire conductors can be connected by simply pressing the coloured pusher.

Simplified testing routines

The prescribed regular tests include measuring the insulation resistance of all conductors to earth in accordance with VDE 0100-718 and DIN VDE 0100-482. The neutral conductors must also be tested individually and electrically disconnected for this purpose. However, disconnection is not permitted according to the standard. With Weidmüller's new modular installation terminals, isolation can be carried out using a standard disconnector or a disconnection slide, depending on the number of circuit groups within a property:

In buildings with many FI/LS circuits, it happens that each room or current path represents a single electric circuit that must be considered separately during measurement. With the AITB modular installation terminals, each N potential can be routed separately via individual disconnectors and separated for insulation measurements.

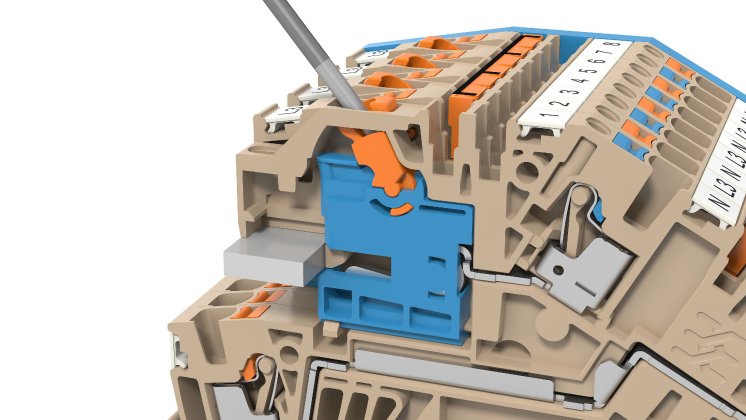

For large circuit groups, copper busbars are usually the means of choice for connecting the neutral conductors. Here, isolating sliders are provided for the required isolation of the neutral conductor during the measurement. If the slider is levered to the end position with a screwdriver, it opens the contact to the copper busbar. The clearly visible position indicator quickly and reliably informs about the current status of the system.

If the electric circuit is interrupted, the actual measurement is carried out conveniently and safely in both cases via the integrated test tap.

Functional diversity made clear

Thanks to their multi-functional disconnection area, the AITB installation terminals are suitable for a wide variety of functions. This disconnection area can optionally accommodate a fuse holder, a disconnector or a component plug. In this way, the terminal block can be used within an application as a disconnect terminal block, fuse terminal block or as a terminal block with electronics installation. So that the overview is not lost despite the numerous connections in the smallest space, the different functional areas of the terminal block systems can be clearly distinguished by shape or colouring. This makes it easy to see which test taps belong to which wire connection. Of course, this also applies to the cross-connections. The common colouring helps to avoid confusion in confined spaces. Installation and maintenance work can thus be carried out in a time-saving and error-free manner.

Service from planning to delivery

To go with the new modular installation terminals, Weidmüller is also offering its tried-and-tested service package that starts at the planning stage – with the digital set-up in the Weidmüller Configurator (WMC). With the Configurator, complete terminal blocks including accessories can be digitally planned, assembled and ordered directly. With the "Fast delivery service", the fully assembled terminal strips are delivered directly to the place of use. At the touch of a button, the Weidmüller Configurator also generates complete parts lists and installation instructions for production. In this way, errors can be avoided and costs saved. And if desired, it also continues at the push of a button, because the modular installation terminals are "ready to robot". This means that they already support robot-assisted installation, marking and wiring through their shape and marker positioning. This means that the user is optimally prepared for the advancing partial automation in panel building.

Weidmüller is continuously expanding its product line in this area. The terminal block systems will then be available in various designs, connection options and colours for wire cross-sections from 2.5 mm2 to 16 mm2. Simple feed-through terminal blocks, neutral and PE terminal blocks with and without automatic contacting to the terminal rail, as well as terminal block systems with several wiring levels are planned. With these, an entire electric circuit with all the associated measuring and test options can be accommodated on just one terminal width.