The EXPO 2020 pavilions stand on land that was previously barren desert. Visitors have 182 days to explore the newly created site before it is transformed into a new Dubai neighbourhood, "District 2020", when the World Expo ends. 80 percent of the buildings and structures built for the EXPO will be retained.

The shading structures covering the walkways between the exhibition pavilions will also continue to be used after the EXPO. These elegant roofing elements provide pleasant shade in Dubai's hot desert climate. Werner Sobek was responsible for these shade structures from the very beginning – starting with the design, general engineering, structural engineering, sustainability concept and support for the certification to CEEQUAL right through to construction supervision. "We are proud that our shade structures played a major part in shaping the EXPO site," declares Holger Hinz, who was closely involved in the project over a period of years in his role as General Manager of Werner Sobek Dubai.

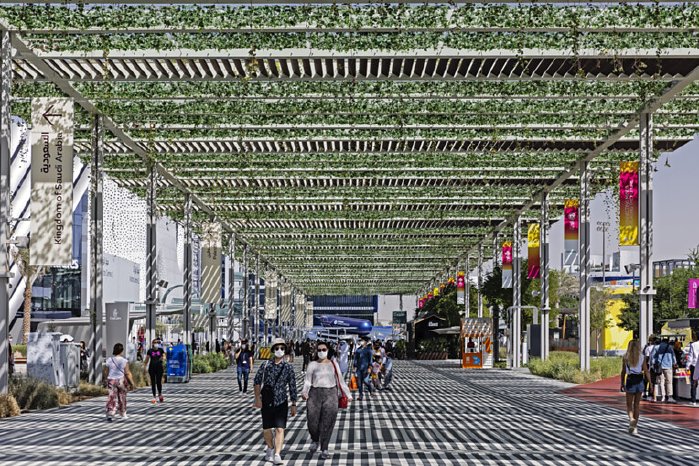

Bird-like shade providers and plant-covered pergolas

Based on the principle of a large-span steel-frame structure, Werner Sobek designed three different shading systems. Varying in their visual impression, they are united by the task of acting as a link: "They provide a harmonious connection between the heterogeneous pavilion buildings without competing against them," explains Marc Gabriel, Werner Sobek’s lead architect in the project. He adds: "The client demanded an architectural and engineering highlight, but one that didn't steal the limelight from the pavilions and still ensured a clear view of them. Comprehensive studies were carried out to determine the precise geometry of the sunshade roofs." The shade structures ensure a reduction in ambient temperature of up to five degrees Celsius during the warm months, ensuring a much more pleasant visit to the EXPO in the desert state. "To make sure this was the case, we produced microclimate simulations of the entire public space – including the surrounding buildings and planned vegetation – at several stages in the project," explains Leman Altinisik, one of Werner Sobek’s sustainability experts.

A shading system with around 3,500 bird-shaped membrane figures spanning up to four metres covers an area of 16,400 square metres. The winged elements are supported by multi-layered horizontal wire meshing. Climbing plants provide greenery for the second system. These pergolas feature around 11,000 plants rooted at the shading level and cover an area of approx. 19,000 square metres. Besides creating shade, the plants also provide natural cooling by means of evaporation.

Especially developed high-tech textile

Measuring 56,000 square metres, the largest shading area consists of a canopy made of a non-prestressed fibreglass membrane. The roof construction requires no additional cross members or visible harnesses, making it even more elegant in appearance. Thanks to its lightweight construction, it saves a lot of material and therefore also grey energy and CO2. The high-tech textile covers around 2.7 kilometres of the walkways between the pavilions. The canopy can be retracted to its standby position in no time at all should the wind become too strong. The membrane surface provides shade during the day and acts as a projection screen at night. The textile presented the team at Werner Sobek with huge challenges during both development and production. "The interdisciplinary team of designers and manufacturers minimised the use of material by means of parametric studies," explains Holger Hinz. "The fibre structure follows the distribution of forces and the desired size of the openings in the fabric. It is the first time a multi-axial glass fibre membrane has been realised in connection with a flexible, non-prestressed and moveable structure optimised in terms of load transfer. No flexible non-crimp fabric had been produced on such a scale and in such a quantity before our project. The production systems for the textile were not designed until the sample phase and not built until the contract was signed. Development continued during the manufacturing process."

Designed with sustainability in mind

When conducting his research to identify a suitable material, Werner Sobek placed great importance on a high level of homogeneity, resource efficiency, recyclability and reducing emissions. "It was the choice of material that enabled the design in the first place," says Marc Gabriel. "We also wanted our design to arouse awareness with regard to sustainability."

The shade structures were certified to CEEQUAL Platinum, thus reflecting Werner Sobek's high standards in terms of durable, resource-saving construction. CEEQUAL is the world leading sustainability assessment and awards scheme for construction projects in the fields of infrastructure, landscaping and public realm projects. The excellent certification was due to the structures' excellent properties in terms of dismantling and recycling plus the fact that a very large proportion of the materials used was sourced in the region.

World's largest BIM model

The shading systems were designed in the same overall digital model as all the other EXPO buildings. This BIM model is the largest of its kind in the world. Werner Sobek had to act particularly fast in the design and planning phase, for example presenting the foundation drawings ready for execution in the preliminary phase as these also had an impact on the EXPO infrastructure. Subsequent adjustments were practically impossible as these would also have had an impact on the almost 200 accompanying construction projects on the EXPO site.

Data + facts

Architecture

Werner Sobek, Stuttgart/Germany

Planning period

2017 – 2018

Execution

2018 – 2021

Services provided by Werner Sobek

General planning

Design

Structural engineering

Planning building technology systems

Sustainability concept (use of renewable energy sources and recyclable materials, microclimate optimisation)

Support for CEEQUAL certification

Construction supervision

Gross floor area

96,000 m²

Client

CH2M Mace Joint Venture on behalf of Expo 2020 Dubai, Dubai/UAE

Photography

Andreas Keller, Altdorf/Germany