For the machine building sector this means new challenges with regard to productivity, end product quality, plant availability and engineering flexibility. The urgent need for innovation remains unbroken in all these areas, with the design of the machine's drive train frequently playing a vital role. Since precision and productivity are often constrained by the selected gearhead and motor, improvements to these and other drive components have a significant impact on the machine as a whole - and consequently on their value for users.

SPK+ - packaged power

SPK+, a new right-angle gearhead for applications with high reduction ratios and torques, is alpha's response to the above-mentioned trend. SPK+ combines the best of two alpha product families: the top selling SP+ planetary gearhead ("The New Generation") and the SK+ right-angle gearhead unveiled last year. This alliance promises unprecedented performance in an integrated package crammed with practical new features - benefits for machine builders everywhere:

- SPK+ is more compact, lighter and more economical than conventional bevel planetary gearboxes, which were never well suited for many important applications.

- One gearhead stage less for the majority of reduction ratios: SPK+ achieves higher reduction ratios than other right-angle gearheads with the same number of stages. Not only is it more powerful, it is also more economical. In particular, handling tasks - often necessitating a reduction ratio of i=30 to i=40 - now profit from the superior performance of a planetary gearhead from alpha. Compared to low-backlash worm gearheads, the next smaller size usually suffices.

- The SP+ in the output stage assures impeccable positioning accuracy and perfect synchronism - both lasting a lifetime thanks to the fatigue-resisting design of the alpha hypoid and planetary gearsets.

- Only a third of the weight of low-backlash worm gearheads with similar power transmission - an immense advantage for handling robots and loading/unloading machines with moving drives.

- Low noise level, courtesy of the smooth-running hypoid gearset on the input and the optimized helical teeth in the SP+. On the output side, SPK+ is characterized by significantly lower noise emissions than conventional designs.

- Option of i=16 and i=32 for applications like endless positioning, where binary reduction ratios are a must.

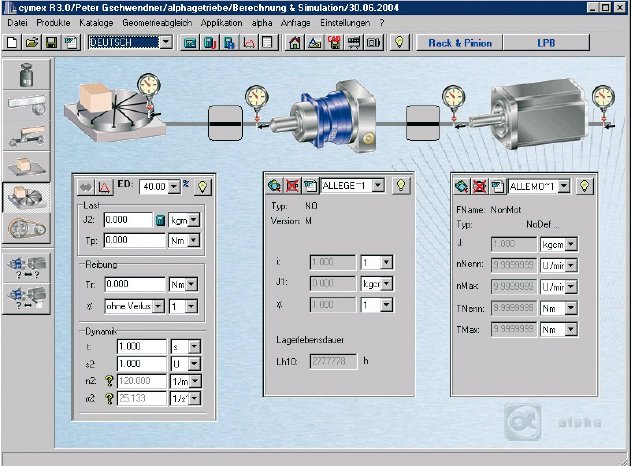

- A host of solutions featuring SPK+, the SK+ right-angle gearhead, alpha's high-precision rack-and-pinion system, TK+ and several further products can be implemented for the seventh axis of industrial robots or other additional axes in robotics applications. cymex 3®, the sizing software developed by alpha, calculates the complete drive unit.

cymex 3®, the most advanced servo gear sizing software in the world, has now been extended to include the new SPK+. It works out all possible solutions to specific drive problems and allows the design to be varied by choosing from thousands of parameter settings. This enormous versatility is attributable partly to the diversity of the gearhead and accessory solutions (pinions, racks, etc.) and partly to the fact that cymex 3® also optimizes the motor selection process. The outcome: greatly appreciated advantages for machine builders.

- SPK+ comes in four sizes with acceleration torques from 80 to 1100 Nm (with 1000 cycles per hour) and 11 reduction ratios from i=12 to i=100.

- The torsional backlash is between 2 and 6 arcminutes, depending on the version (with a deflecting torque equivalent to 2% of T2B).

- Thanks to the universal alpha motor mounting system, all popular servo motor types can be easily mounted. The gearhead output is compatible with SP+, the de facto industry standard.

- SPK+ is usually dispatched within one to two weeks. Technical support and customer service are available worldwide through alpha's own sales companies and agents.