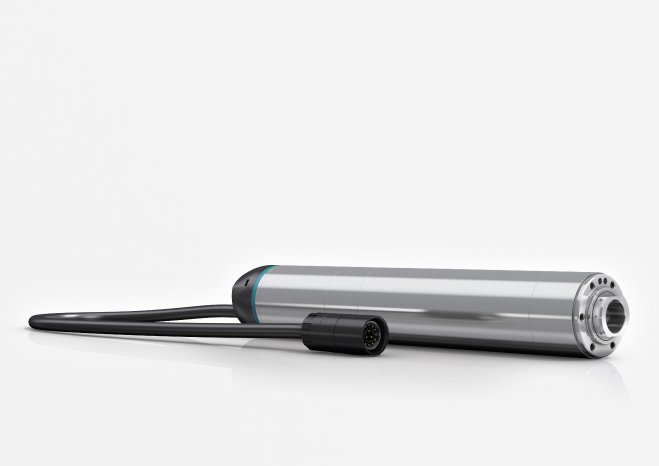

The small servo motors have an integrated screw and are permanently lubricated, so that no maintenance is required; they make a perfect complement to the existing portfolio of rotary servo motors and actuators in the cyber dynamic line family. They are used, for instance, for positioning, joining, bending, gripping and dispensing in reshaping and handling applications, the semiconductor industry, packaging machinery or assembly automation. The 100% stainless steel design with IP65 protection also creates numerous interesting applications for the new, integrated linear actuator in food and beverage plants, such as in highly precise bottling lines.

High power density in an industrial design

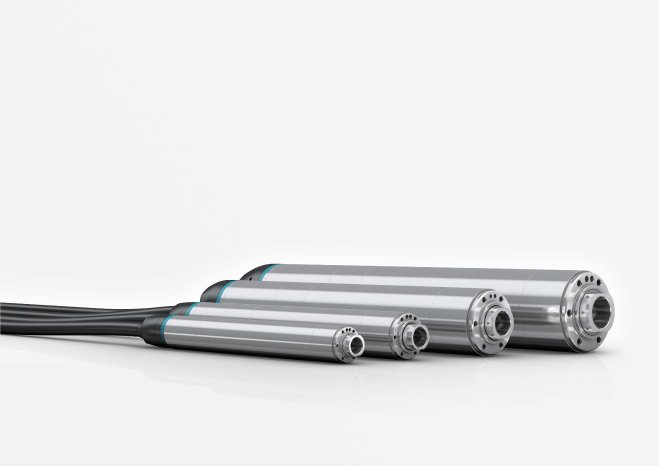

With their high power density and dynamics, the new small servo motors with an integrated screw are particularly impressive in action. Each of the four sizes(outside diameter 17 mm, 22 mm, 32 mm or 40 mm) achieves excellent acceleration values, cycle rates and machine throughputs in a very small space. This is due to the compact design, which results in much lower mass inertia than is possible, for instance, if the screw is simply attached to the servo motor. The strictly industrial design was another top priority. The complete actuator is accommodated in a robust stainless steel housing with IP54 protection and can be mounted in any position. The screw itself is maintenance-free with an anti-rotation mechanism and fits inside a closed thrust tube. The spindle drive and reinforced bearings allow both a tensile and a compressive force to be applied. An absolute single-turn encoder system with 12-bit resolution is available for all sizes. If the 32 or 40 size is installed, the functionalities of what is currently the smallest integrated multiturn encoder in the market can additionally be implemented as an option. All sizes are moreover designed using EMC shielded single-cable technology which is suitable for cable carriers. Thanks to these innovative features, the actuators are perfect for industrial applications.

More reliable and more energy efficient than pneumatics

Unlike pneumatic cylinders, the new linear actuators permit precise and flexible position control regardless of the application without any retooling on the machine. They are thus ideal whenever frequent format changes are required. The servo technology offers better controllability by design; together with the easy connection to a higher-level controller, this facilitates reproducible processes which can be either stroke or force optimized. The actuators are leakproof and far more energy efficient in normal operation – after all, compressed air is not only expensive to produce but a significant share of it is lost. Finally, servo technology is virtually maintenance-free and also quieter – two further benefits compared to pneumatics.

Impressive connectivity in the system

The new small servo motors with an integrated screw can be configured with simco drive servo regulators to form high-performance small servo axes. Multiple connection options are available for these solutions, which can be integrated in a higher-level controller via CanOpen, EtherCAT, Profinet RT/IRT or EtherNet/IP. At the same time, this single-source system solution entails absolutely no interface risks and has an electronic identification plate that reduces the time for commissioning. As another software feature to simplify start-up, the end positions are automatically limited, preventing the actuator’s mechanical stops from being approached dynamically. By selecting the electronic homing mode, the machine operator can define any zero position and home to it freely.

These small servo motors with an integrated screw in the cyber dynamic line series are ideal whenever a strictly industrial design, high compactness and dynamics, multiple interfaces, optimal energy efficiency and permanent freedom from maintenance are called for.