The ideal drive system for any application

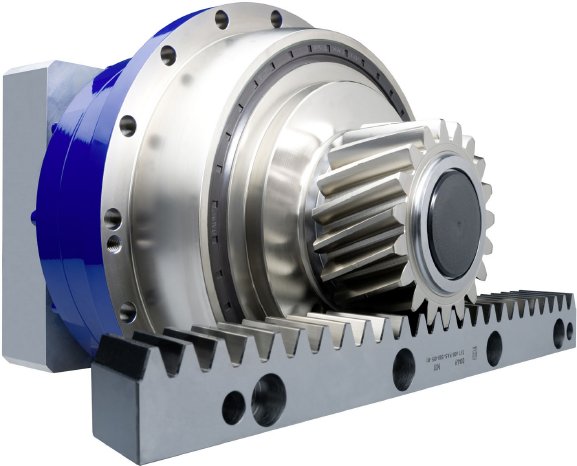

Rack-and-pinion drives are no exception, of course. Thanks to WITTENSTEIN alpha GmbH's vast sizing expertise, backed up by a similarly extensive portfolio of gearheads, racks and pinions, individual users are sure to find the ideal system for their particular application.

Typical applications

Regardless of whether the customer is aiming to speed up the 25 ton gantry of a machine tool, position a laser cutting head at 400 m/min or execute welding operations with a tolerance of just 0.1 mm using a jointed-arm robot, WITTENSTEIN alpha's rack-and-pinion drives guarantee maximum precision, dynamics and running time plus optimal efficiency. Owing to their operating principle, there is no restriction on the length of these drives, which is why they are perfect for applications with long travel distances. The fact that the racks can be sorted assures consistently high precision irrespective of the axle length.

In view of the wide range of rack classes, gearhead types and pinion connections, it is possible to configure the ideal system for almost any application. The experts at WITTENSTEIN alpha don't simply rely on the experience amassed over more than a quarter of a century, however - they also make use of the latest simulation and analysis tools.

Leader in energy efficiency

Compared to linear drives, the traditional rival technology, rack-and-pinion drives provide clearly superior energy efficiency: whereas in practical duty ball screw drives and linear motors only rarely exceed the 90% efficiency mark, WITTENSTEIN alpha's rack-and-pinion system achieves up to 97%. The resulting energy savings are considerable, especially in applications with high duty cycles.

Technical specifications of WITTENSTEIN alpha rack-and-pinion drives

- Max. travel speed: 440 m/min

- Max. feed force: 47 kN with one drive

- Max. precision: 5µm with direct measuring system

- Max. input torque: 3654 Nm

Portfolio of WITTENSTEIN alpha rack-and-pinion drives

- Racks with 2 to 6 mm module

- Lengths up to 2000 mm

- Total pitch deviation up to 12 µm/m

- Servo planetary and worm gearheads

- Right-angle and coaxial gearheads

- Torsional backlash < 1 arcminute

- Innovative pinion connection for very high rigidity