The industrial implementation of the digital twin as well as smart products and services with which the WITTENSTEIN group is playing a key role in shaping and developing the world of cybertronic motion and digital transformation will also be among the highlights on show in Hannover.

Indeed, this has been the story for four decades now: 40 years ago, in 1983, WITTENSTEIN unveiled the world’s first low-backlash planetary gearhead at the Hannover Messe. This invention simultaneously marked the birth of the present WITTENSTEIN alpha GmbH – still one of the leading suppliers of precision gearboxes worldwide to this day. Another landmark innovation in drive technology during this 40-year period was the Galaxie® drive system in 2015, which subsequently not only won several prestigious awards but also convinced users in the high performance engineering sector. It has since been mathematically proven and recognized in the research community as an independent gearbox class.

Galaxie® in miniature – with axial function principle and unrivalled performance

WITTENSTEIN’s miniaturized Galaxie® gearbox will make its debut at the 2023 Hannover Messe. With its small sizes and high overall ratio, this ultra-rigid, high precision gearbox is an installation compatible, technically and technologically superior alternative to strain wave gearboxes of the kind commonly employed in medical and precision robotics. A brief comparison of the technical data provides sufficient confirmation: 40% higher compactness and torque density, three times better torsional rigidity, double the emergency stop torque, absolute zero backlash throughout its entire lifetime and an almost 50% larger hollow shaft diameter add up to a new performance dimension in the market-compatible 90 mm and 110 mm gearbox sizes. Together with the servo motors in WITTENSTEIN cyber motor’s cyber® kit line series, the miniaturized Galaxie® gearbox moreover forms a perfect motor / gearbox combination – although hollow-shaft motors from other manufacturers can likewise be integrated if desired.

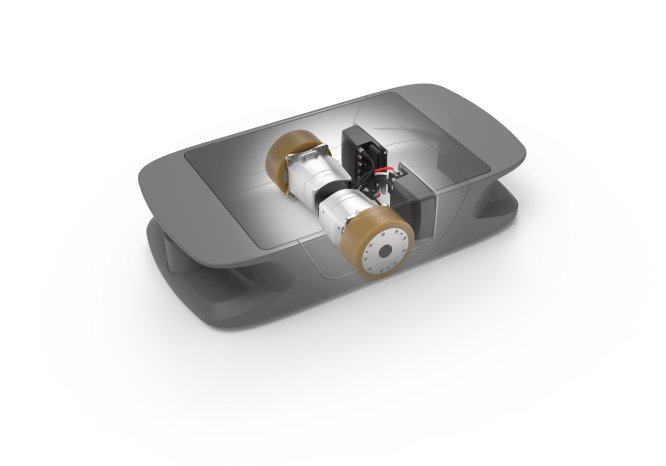

cyber® iTAS® system 2: New servo drive system for AGVs, AMRs et cetera

The cyber® iTAS® system 2 from WITTENSTEIN cyber motor is a completely redesigned, compact servo drive system for AGVs (Automated Guided Vehicles), AMRs (Autonomous Mobile Robots) and other mobile platforms. This differential drive system convinces with an end-to-end industrial concept that will greatly simplify vehicle development, design and construction in the long term along with operation and servicing. The cyber® iTAS® system 2 consists of a safety certified servo drive and a wheel actuator just 180 mm high with an increased load capacity. The safety architecture of the drive system has been redesigned too: with its unusually lean design, it ensures maximum ease of integration.

The drive system’s performance and safety features are ideal for AGVs and AMRs in both conventional and collaborative working scenarios in production, assembly, warehouse and intra-logistics. It gives vehicle manufacturers the capability today to build AGVs, AMRs and other mobile platforms that will fully satisfy the requirements of the factories of the future.

Digital twin / smart products & services

Everyone is talking about the digital twin – and at the upcoming Hannover Messe, WITTENSTEIN will be demonstrating how it links a product’s life and usage cycles plus the benefits it brings for machine construction companies and users alike. The latest smart products and related digital services will be on show as well, for example gearboxes with cynapse® functionality that generate usage data, keep statistics on potential causes of failures or provide service information.