- Model facelift: Presentation of the two gearheads at the Hanover Fair 2009

- Resource efficiency: More power in a smaller package

- Guaranteed compatibility: External and connecting dimensions remain unchanged

- WITTENSTEIN AG - Hall 14, Stand J04

"Models of perfection" - this is how WITTENSTEIN alpha of Igersheim in South-West Germany describes its re-innovated SP+ and TP+ series of gearheads, on show at the forthcoming Hanover Fair. The WITTENSTEIN subsidiary has subjected both gearhead families to a technical and visual facelift. However, customers can rest assured that all critical external and connecting dimensions will remain unchanged. All existing gearheads can be replaced with the facelifted SP+ and TP+ types quickly and easily, in other words, without any complicated conversions.

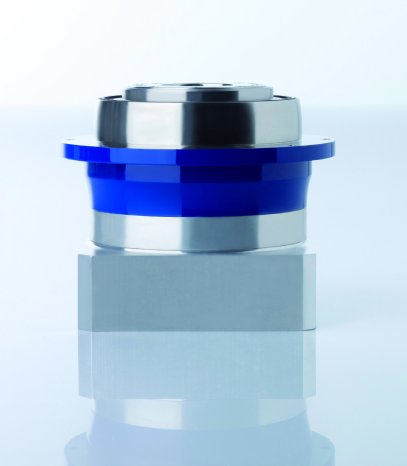

The upgraded models are a renewed demonstration of WITTENSTEIN alpha's undisputed excellence in the field of mechatronics. This leading drive manufacturer has succeeded in improving the ingenious concept of its alpha SP+ and TP+ gearheads still further. The two gearhead series are the outcome of twenty-five years of engineering experience that also forms the backbone of the company's all-round consulting expertise. It is the interaction of these two factors that turns every WITTENSTEIN alpha gearhead into a "model of perfection". At the same time, the SP+ and TP+ have been given a new, more modern design. After all, the technical perfection on the inside must simultaneously be clearly visible on the outside.

What's more, the torques are significantly higher - up to 25%, depending on the version - thus raising the power density of what are in any case incredibly compact gearheads. Users can profit from this extra torque to "downsize", that is to say they can select a smaller - and hence cheaper - gearhead without compromising its specification. The optimal gearhead design can be determined with the help of WITTENSTEIN alpha's new cymex®3 sizing tool, which additionally features an integrated calculator for energy consumption. Efficient utilisation of energy is guaranteed from the outset.

The permissible radial forces of the SP+ gearheads have likewise been improved, making these types more robust than ever. This also gives customers the welcome liberty to choose a smaller and more efficient size. Finally, the optimised teeth ensure an even higher level of reliability in day-to-day operation.

Maximum design freedom and flexibility are important criteria upfront of any gearhead purchase. Once again, WITTENSTEIN alpha has listened to its clients' needs and now offers a drive version with a hollow shaft and clamping set for its SP+ family. For the same reason, the company has adopted a modular design concept for its SP+/TP+ gearheads in conjunction with the hypoid series.

When developing the latest enhancements to the SP+ and TP+ series, the engineers responsible were careful to consistently apply a principle of resource efficiency, a topic that has long been a central element of everything WITTENSTEIN does. The company takes a holistic view when it comes to the optimal deployment of raw materials. This is another instance where the cymex® software merits special mention - in addition to sizing complete drive trains quickly, efficiently and effectively, it now also calculates the energy consumption. This saves not only power and energy but also time - an equally vital resource.

Besides offering unparalleled power density, the newest generation of the low-backlash planetary gearheads is also quieter than ever before. Contrary to popular opinion, noise can make a not inconsiderable contribution to indirect costs.

Machine downtime can be reduced to a minimum on the one hand by reliable and durable gearheads and on the other by punctual deliveries. WITTENSTEIN alpha's recipe here is the successful 'Speedline' service that guarantees dispatch of all standard gearheads in just 24 hours.