The exhibits of the four WITTENSTEIN subsidiaries attending the exhibition - WITTENSTEIN cyber motor, WITTENSTEIN motion control, WITTENSTEIN alpha and WITTENSTEIN electronics - will show how requirements such as robustness, functional safety, freedom from defects, reliability, safe operation and data security are built into the Group's various products and solutions as central features. This will be illustrated particularly clearly by an exhibit at the WITTENSTEIN booth which is based on a real customer application at STIWA Automation GmbH of Austria.

STIWA: Safe and reliable control of very high dynamics

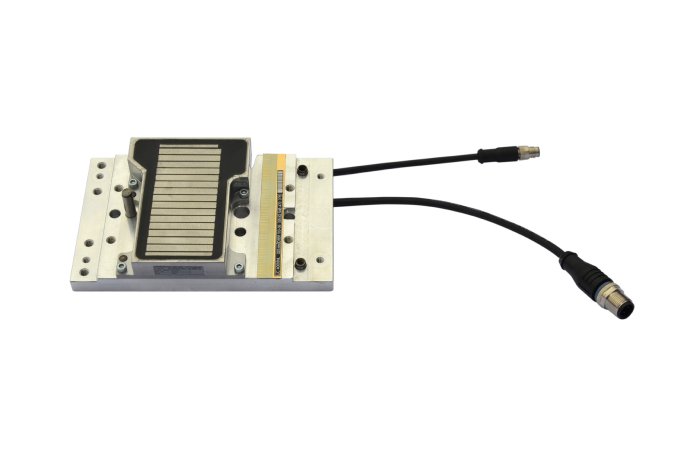

The ability to control very high dynamics is a fundamental aspect of safety and reliability in the linear motor technology developed by WITTENSTEIN cyber motor and integrated in STIWA Automation's high performance assembly systems. What originally began as a one-off, customized application inspired by the "cyber linear motors" product family was gradually optimized as a result of close cooperation between the two companies to produce a solution that meets the specific requirements of STIWA's new LTM-CI high performance assembly system. The stator unit and the rotor with its high performance magnets, for instance, form an integrated, power dense motor unit which facilitates safe and reliable control when very high dynamics and precision are vital. The solution package put together by WITTENSTEIN cyber motor also includes rotary motors in the "cyber power motors" family as direct drives for the chain of the pallet transport system.

The LTM-CI allows small parts to be assembled fully automatically and absolutely precisely at a cycle rate of 0,6 seconds per part in order to obtain bigger units. To enable components such as these, which are hardly any bigger than a pinhead, to be assembled with the necessary reliability, they have to be positioned and mounted not only extremely accurately but above all extremely fast. STIWA relies on linear motor technology from WITTENSTEIN cyber motor for this purpose: gripper speeds of up to 2 m/s are now possible in stable, reliable processes in combination with controlled, jerk-free positioning profiles.

Solutions for markets where safety and reliability are crucial

The safety, security and reliability requirements a mechatronic drive solution is expected to fulfil vary considerably from one market and from one application to another. Whenever food products have to be processed and packaged, for example, compliance with the very highest hygiene standards is a top priority. Drive solutions in stainless steel housings, whose smooth surfaces and lack of dead spaces prevent bacteria from accumulating, make a valuable contribution here.

Responding to this need, WITTENSTEIN motion control will present "axenia value" - a complete series of stainless steel actuators for torques from 32 to 200 Nm.

Through its TPM+ servo actuator family, which includes a motor encoder variant with a DRIVE CLiQ interface and integrated safety functionality, WITTENSTEIN motion control also helps promote "functional reliability".

"Factor S" also implies maximum investment and future security

No matter which other aspects are relevant or prioritized, "Factor S" invariably includes long-term security for the customer or user's investment; after all, only efficient and controllable mechatronic drive solutions are successful in the long term - not only from a technical point of view but also commercially - and hence future-proof.