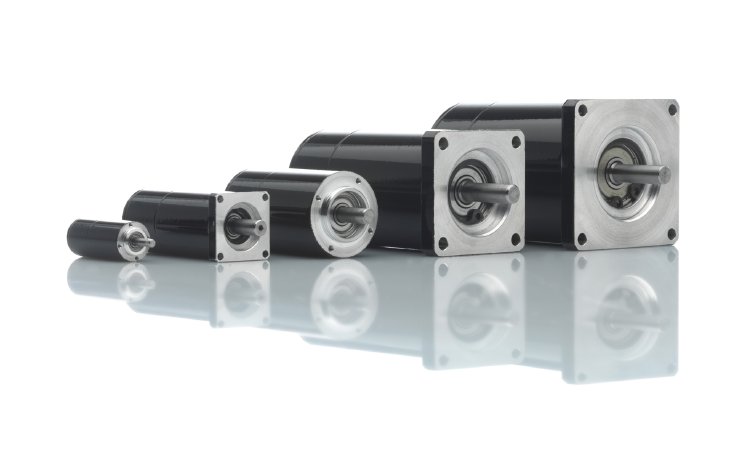

The limited diversity and largescale production of the new motors means they can be offered at a much lower price than WITTENSTEIN's existing series. Despite this, they unite all the characteristics that are crucial for highend applications without compromising quality.

Innovative branches of industry call for motors that are capable of precise traversing and positioning at high speeds. WITTENSTEIN cyber motor's industrial line provides topquality solutions that satisfy even the toughest industrial specifications. The simplified selection and implementation philosophy speeds up the sizing and enquiry process enormously. It is embedded in WITTENSTEIN's special sizing software, which includes options for defining drive requirements with only a few clicks of the mouse, generating 3D models and submitting requests via the integrated product configurator. WITTENSTEIN cyber motor then determines the most suitable product quickly and efficiently in a dialogue with the customer.

New electromechanical characteristics

Thanks to their high fill factor and high pole number, the motors are especially convincing at low to medium speeds. This behaviour is typical of direct drives. The motorgearhead configurations that are extremely common in the small motor segment, for example, can thus be phased out in favour of industrial line motors. Alternatively, when used in conjunction with a gearhead, these motors allow relatively high torques to be produced at low gear ratios. In addition, the new 12bit encoder system is compatible with the MINI-IQ-Drives® controller series, enabling the absolute position to be stored and facilitating an accuracy of ±20 arcminutes.

Whereas in the past, the combination of high gear ratios and high speeds was frequently a cause of suboptimal gearhead efficiencies, this problem is now virtually eliminated by the ultraefficient industrial line motors. The outcome: an exceptionally efficient system.

Technical features:

- High power density due to the high fill factor and special winding process

- Strong torque due to the multipole design

- High dynamics due to the low mass moment of inertia and high maximum torque

- High efficiency up to 94%

- Easy mounting with different flange and shaft variants

- Smooth running due to the optimised detent toque

- Spacesaving design in a compact housing

- Maintenancefree philosophy

- Simple connectivity with combined plug connectors for signals and power

- Precise positioning and stability of the synchronised speed due to the small mechanical tolerances

- Building block system that can be optionally augmented with a gearhead, encoder, brakes and electronics

- 12bit encoder system as an absoluteincremental encoder in conjunction with the new WITTENSTEIN MINI-IQ-Drives® controller series

Typical applications:

- Machine tools

- Robotics

- Component placement

- Handling systems

- Automation technology

- Packaging machines