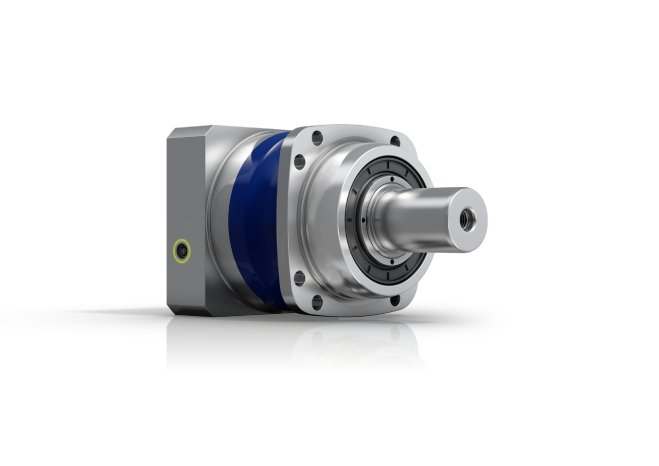

The XP+ HIGH TORQUE stands for systematically increased performance and space-saving downsizing. Furthermore, thanks to cynapse – an integrated sensor module with a data logger and an IO-Link communication interface – this gearbox enables future-proof connections to digitalized drive axes and machines.

Machine tools, packaging equipment, automated handling systems and special-purpose machines profit especially from the performance characteristics of this new, WITTENSTEIN-built premium gearbox. It is first choice in any application where

- Very high positioning accuracy and repeatability are called for,

- Frequent changes of direction are the norm,

- Very short cycle times are required, and

- Maximum compactness and space savings matter.

As the high-performance addition to the XP+ family, the XP+ HIGH TORQUE gearbox is designed to provide best-in-class precision, dynamics and power density – and it is regarded as the benchmark gearbox technology in all key disciplines. It achieves significantly higher process, feed and lever forces, unlocks extra dynamic potential and convinces with further improved control quality, precision and positioning repeatability. This results on the one hand in clearly enhanced performance, taking machine development into totally new dimensions, and on the other in systematically downsized drive solutions thanks to the enormous potential savings in space and weight. As with all gearboxes in WITTENSTEIN alpha’s Premium segment, torsional backlash remains constant at less than one arcminute over the entire service life.

Industry 4.0 connectivity made easy

The XP+ HIGH TORQUE can be equipped with a smart cynapse module for integration into digitalized machine axes and networked production environments, allowing digital services to be used to monitor processes, increase machine uptime or detect faults predictively. The new series will kick off with a coaxial planetary gearbox in four different sizes, with five gear ratios and three output shapes on offer. Other variants are in preparation or can be adapted to specific customer requirements on request. WITTENSTEIN alpha’s cymex® 5 software and in-house engineering expertise are invaluable aids when deciding which gearbox version best matches a particular application.