The entire process runs as a background process in "silent mode". The WSCAD software does not need to be started, and even the users themselves need not be present during the creation of the plan. Software controls software - a step toward Industry 4.0. Because the interface is web-based, remote connectivity can be used as well. Clients can thus initiate the construction of a control cabinet or make changes in a schematic in the WSCAD systems of their service providers "over the network and at night" directly from within SAP, for example.

"The Automation Interface decreases development time significantly", said Jürgen Panhölzl, Head of Global Business Services at WSCAD, in a comment about the new feature. "The mechanisms for reuse and automation embedded in the WSCAD software are the keys to ensuring the consistently high quality of the work results." Users can enjoy tangible benefits: greater transparency in the entire engineering process, faster offers, shorter response times, lower costs and, ultimately, increased customer satisfaction.

Most recently, with spyydmaxx from ACATEC, we already have the first product configurator that uses the automation interface of WSCAD. With the spyydmaxx software, ACATEC is developing and distributing a solution for configuring machines and equipment. The ACATEC WSCAD solution, which was primarily available only in the field of mechanical engineering thus far, is now also mapping the field of electrical engineering for the first time. In the case of a motor, for example, information on the performance class, manufacturer and type of control can be stored in the configurator, and WSCAD can then instantly generate a suitable schematic or cabinet layout at the touch of a button.

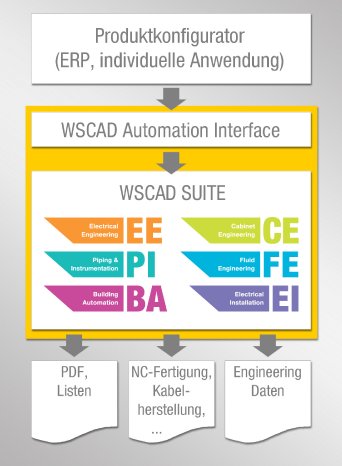

The Automation Interface is an add-on for WSCAD SUITE and works smoothly together with all six disciplines: Electrical Engineering, Cabinet Engineering, Piping and Instrumentation (P&ID), Fluid Engineering, Building Automation and Electrical Installation.