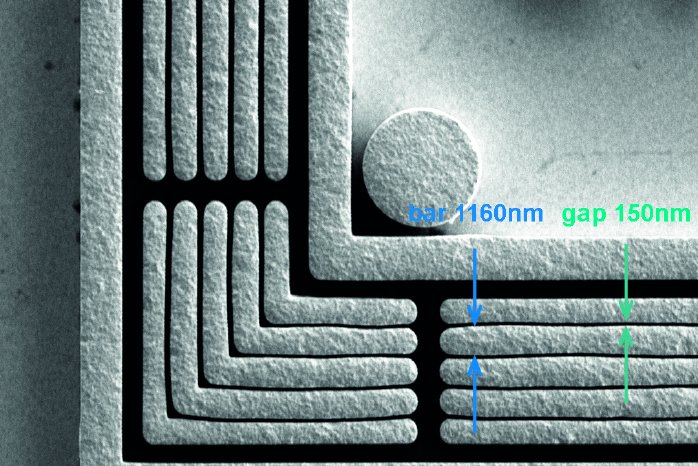

This unprecedented 150 nm detail visibility, even in the presence of high levels of energy, is made possible for the first time due to an extremely small focal spot displayed by the water-cooled, 190 kV nanofocus tube that has been newly developed by YXLON in Hamburg. In addition, new CT algorithms provide optimum image resolution in the event of a larger field of view (FOV). The new ScanExtend feature offers a horizontal FOV extension and is ideally suited for larger inspection items or enables smaller inspection items to be magnified to an even greater degree. The scan is implemented during a complete rotation of the inspection item, then reconstructed free of artifacts. This, in turn, leads to a time savings, unlike the case with conventional algorithms that utilize so-called ‘stitching’, which makes them more time-consuming. What’s more, new developments such as the virtual rotation axis and the HeliExtend feature (Helical CT) increase the breadth of application, the quality of inspections and the time efficiency for the application user to an even greater extent. For example, this is of particular benefit in the case of small, vertically elongated parts such as 3D printed nozzles.

YXLON has set off on completely new paths with the FF20/35 CT systems and the Geminy system platform: Intuitive smart-touch operation, remote monitoring, push messages and different user profiles make it possible for the systems to be operated without special prior knowledge and skills. The large inspection envelope in conjunction with the tube and detector assemblies provides for a large range of applications and a great deal of flexibility. “This new release proves that we are complying with our customers’ wishes. The highest image quality, simple, intuitive operation, maximum flexibility and efficient workflows are the prime decision-making criteria when purchasing an inspection system. Our FF20/35 CT systems supply all these factors, combined with lots of features that enable any user to achieve what are simply the best results,” explains Peter Kramm, Senior Product Manager at YXLON.

In the meantime YXLON has fully equipped its application centers with the new YXLON FF20/35 CT systems on a worldwide scale. Interested parties can now have the systems demonstrated to them not only in Hamburg and Heilbronn/Germany but in Hudson in the USA, in Shanghai/China, Yokohama/Japan and Taipei/Taiwan. There they can convince themselves of the advantages these systems have to offer.