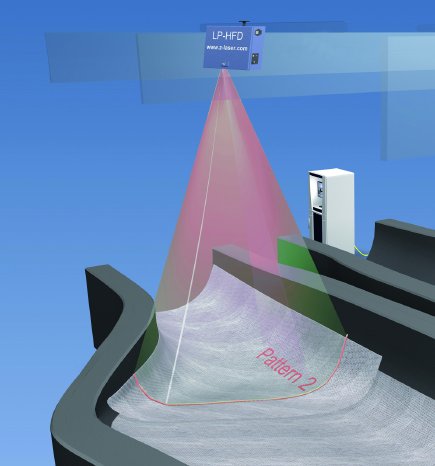

Project, mark and control with the help of laser projectors: Exact positioning of work pieces or viewing the next work step by the laser light for large surfaces offer considerable advantages. Set patterns of fiber mats are created faster, the manual correction is significantly reduced, and the quality is constantly kept high. An optimal order and placement is achieved by taking care of the individual material properties. A 50Hz flicker-free laser projection of words or numbers, for example for the tool selection, is also possible and then serves as an installation support.

The custom-built software (LPM) allows a complete control over the laser projector from the PC and is flexible in its design. Data for each of the required projections can be transferred serial, via RS-232, Ethernet or optional WLAN. As well, the laser projector LP-HFD can be extended with a freely configurable industrial remote control to switch the subject directly on the work place. Two needs-adapted versions of the laser projectors are available with opening angles of 80° x 80 ° for wide area coverage or 60° x 60° with higher repetition rate for more accuracy. To cover complete wind wings with a laser field in the production halls, usually a multi projection system is used, where multiple projectors are connected in series. The system is equipped with a temperature drift compensation to ensure always an exact display in changing environments in warm halls. Additionally the case housing can be upgraded with an active air or separate water cooling.

Exhibition HUSUM WindEnergy 2012: Hall 4, Stand D06, 18. - 22. September