The three member companies will present their coordinated production line for metallic bipolar plates.

Additionally, they will share the latest expert insights into bipolar plate production at two key sessions.

A Perfectly Coordinated System for Efficient Bipolar Plate Manufacturing

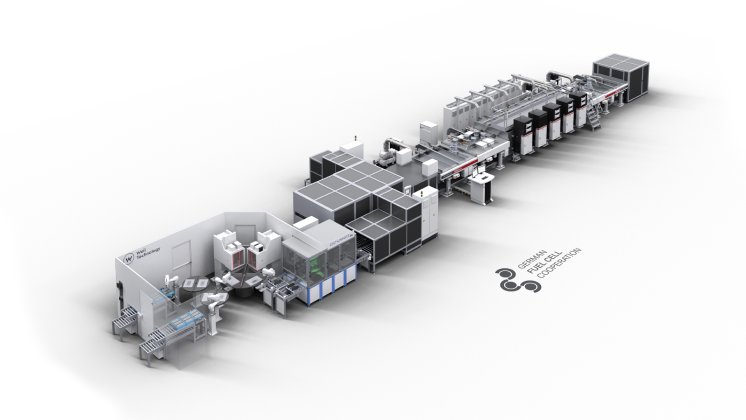

The German Fuel Cell Cooperation (GFC), a partnership between VON ARDENNE (Dresden), Weil Technology (Müllheim), and ZELTWANGER (Tübingen), is showcasing its coordinated production line for metallic bipolar plates at hy-fcell 2024.

Each partner is a leader in their respective field. Therefore, they bring their specialized expertise: VON ARDENNE for advanced coating, Weil Technology for high-precision laser welding, and ZELTWANGER for automated leak testing.

With an annual capacity of several million bipolar plates, the fully integrated production line meets the growing demand of the industry.

GFC will contribute to the knowledge exchange at hy-fcell in two key sessions:

Speaker’s Corner: Three GFC experts will discuss production efficiency. Susann Puppe (VON ARDENNE) will cover PVD coating for PEM applications. Dr. Thomas Frey (Weil Technology) will highlight laser-welding concepts for bipolar plates, and Jochen Kober (ZELTWANGER) will emphasize leak testing in fuel cell production. These talks will offer valuable insights into optimizing scalable manufacturing processes.

Conference Session: The GFC experts will join industry leaders to discuss the complexities of bipolar plate production and strategies for improving efficiency in mass production. This talk will be part of the "Fuel Cell Production VI: Stack-Assembly" session, which will be organized by Fraunhofer ISE and moderated by Dr. Ludwig Jörissen (ZSW).

Booth & Contact

Date: 8 – 9 October 2024

Booth: 4E30

Web: www.messe-stuttgart.de/...

VON ARDENNE

VON ARDENNE develops and manufactures systems for the industrial vacuum coating of materials, such as glass, wafers, metal strips or polymer films. Depending on the application, these coatings are one nanometer to a few micrometers thin and give the materials new functional properties. Our customers use these materials to produce high quality products, such as solar cells and solar modules, architectural glass and vehicle glazing, fuel cells, lithium-ion batteries or microelectronic components for sensor systems and optics. Systems and components provided by VON ARDENNE make an important contribution to protecting our environment. They are crucial when producing products that help to consume less energy or that generate energy from renewable resources.

With more than 60 years of experience in electron beam technology and 50 years of experience in magnetron sputtering, VON ARDENNE is a pioneer and worldwide leading supplier of systems and technologies in PVD thin-film and vacuum process technology. We offer our customers technologically mature vacuum coating systems, comprehensive expertise, and global service. The key components are developed and manufactured in-house at VON ARDENNE.

Weil Technology

As a machine builder and solution provider, Weil Technology helps to implement new production processes in sheet metal processing and to optimize, automate and make more sustainable existing sheet metal processing.

The company's core expertise is machines for sheet metal processing via laser welding and laser cutting. Weil Technology can look back on over 35 years of experience here. At the company head office in Müllheim in Baden-Württemberg, approximately 250 employees develop and produce custom concepts and systems.