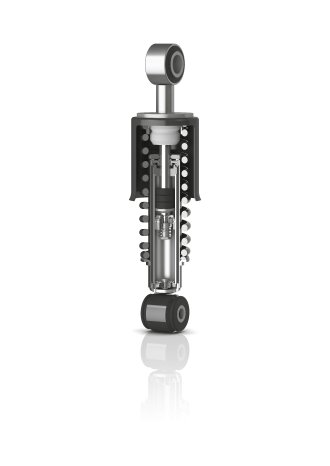

The steel-spring module (Fig. 11) is the standard solution for cabins in construction machines, delivery vehicles, tractors, and special-purpose vehicles. The advantages of steel springs in cabin dampers include simple installation by vehicle manufacturers, compact dimensions, and operations that do not require pressurized air.

Air springs for higher demands

The air-spring module (Fig. 12) provides considerably greater comfort. It is especially suited for installation in vehicles that carry a wide range of different loads – including in the cabin itself. It compensates for different cabin furnishings, and ensures very comfortable damping and suspension performance.

CALM: Cabin Air Levelling Module

A further development of the air-spring module is the Cabin Air Levelling Module (CALM), which ZF developed together with Wabco. This module contains an integrated ride-height control system for the cabin. Depending on cabin height, a valve regulates the pressure in the air spring. CALM (Fig. 13) offers all the advantages of air springs, and in addition, its integrated height-control valve reduces the dimensions and simplifies installation. This additionally increases the reliability of the ride-height control system and prevents a dirt-related failure of the control valve.

Greater safety and comfort as well as health protection with electronically controlled CDC system

Vehicle damping must meet complex demands. On the one hand, it is supposed to enhance comfort and to protect the driver and the vehicle. On the other hand, it has to ensure sufficient driving stability. The optimum adjustment for shock absorbers is therefore always a compromise: Less damping enhances driving comfort, whereas a very high level of damping serves the stability of the cabin.

This is where CDC (Fig. 14), the electronically adjustable damping system from ZF, comes into play. The technology is already successfully used in passenger cars and commercial vehicles and has now been implemented for cabin damping for the first time. The control system permanently monitors all influences such as driver actions and vehicle movements, and controls the CDC dampers accordingly. The combination of a proportional valve on the damper and an electronic control unit enables damping forces to be adjusted in fractions of a second as required by any given driving situation. The system is working on the base of the “skyhook” principle which guarantees the maximum effect on the cabin movement.

The benefits of CDC are obvious. For one thing, it considerably enhances ride comfort, such as when drivers face changing conditions (off-road, on-road, etc). Moreover, it reduces strain on vehicle components and thus lowers maintenance costs. Dynamic adjustment of the damping forces decreases driver fatigue, thus keeping their performance levels high for longer periods of time and protecting their health.

A positive driving experience in the tractor is no luxury, but the precondition that the driver can work with his vehicle safely, relaxed and attentively. As a system supplier ZF develops and manufactures cabin suspensions for all tractor applications – including springs, vibration dampers and rubber metal components. In this context the solution offered by ZF is optimally adapted to the specific requirement. The drivers are profiting from a comfortable working place especially with significantly reduced cabin movements.