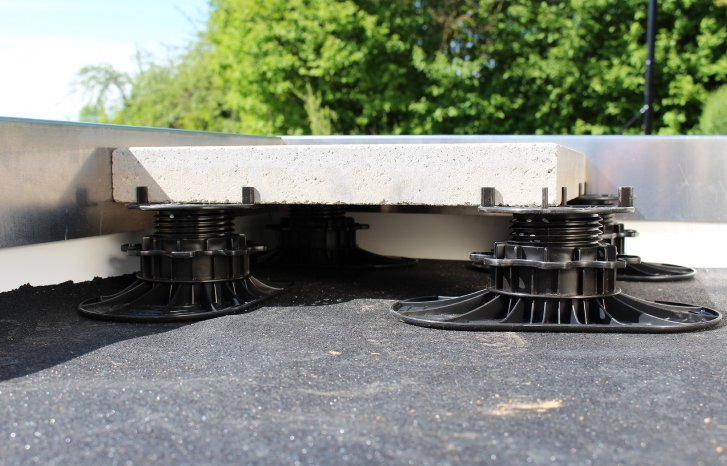

In addition to a low intrinsic weight, installing flooring on pedestals has other advantages: the void beneath the flooring ensures good drainage even on flat roofs, it provides good aeration and space for any pipes that may be needed, and it fully prevents weeds growing in the joints. How does installation with the Elefeet pedestals work?

The new Elefeet pedestals are 20% more durable than their predecessors and now have an elongated base plate which allows them to be placed directly at the roof edge. The base plate now only has to be cut for the corner which is easily done thanks to the pre-marked line beneath. Four different standard versions are used for elevations of between 27 mm and approx. 200 mm, which are adjustable with millimetre precision. The height can even be increased to 500 mm with the correct extension pieces. Very few products on the market actually achieve this range. The ZinCo attention to detail truly comes into its own where the slabs are to be laid diagonally to the edge, large insulation wedges have to be bridged and the flooring has to be extended as far as the door exits. A cantilever arm support, a mitre cut support and much more allow for virtually any flooring to be used in almost any construction situation.

The new Elefeet rail system is a quick and stable addition to the range. The rails are levelled using the two external pedestals, and only a few Elefeet elements are needed in between. A stable flooring structure is created using spacers between the rails and edge retainers for the slabs. Therefore, this design does not depend on a fixed border (upstand, rising wall) all around and the structure can even be completely moved after assembly given the diaphragm effect With the modular system, any geometry is possible, even stairs and steps are easy to design with it.

The various components are connected in an intelligent and therefore quick manner. First of all, retainer clips are clipped onto the Elefeet pedestals without the need for a tool, and the rails are clipped into these clips. The extruded aluminium profiles have double grooves on the side in which the punched studs of the rail connectors are positioned, flush and friction-locked. This prevents twisting and only a small screw on each side is required for fixing in the screw groove. There is no need for time-consuming pre-drilling Support plates are then placed on the rails, as required. They only have to be screwed to the rail at the edge area or in the case of high stress. Once the sub-structure is fitted, the flooring can be installed in no time at all, be it concrete or natural stone slabs, wood or WPC decking. Also ideal for thin-layered ceramic flooring, as you just have to work here with additional cantilever plates. And the entire system is weatherproof and can therefore be used again, for example, where a wooden deck has to be replaced.

Please watch the video

https://zinco-greenroof.com/...