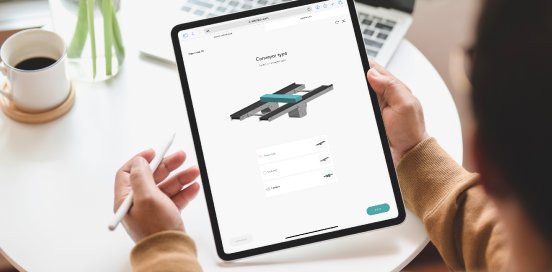

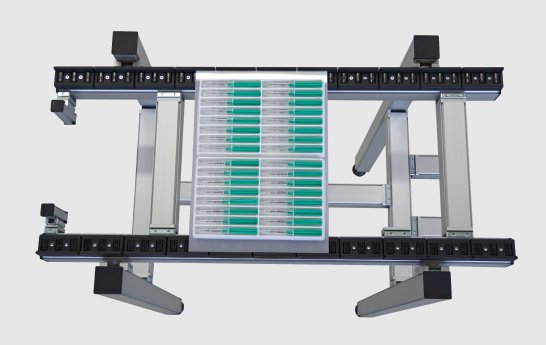

Custom Conveyors Made Simple: Configure with Montech

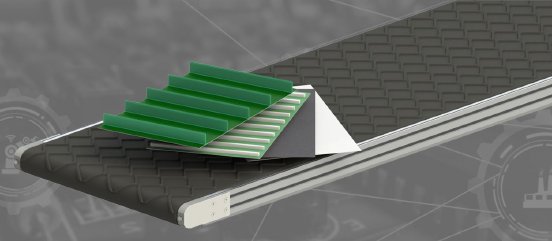

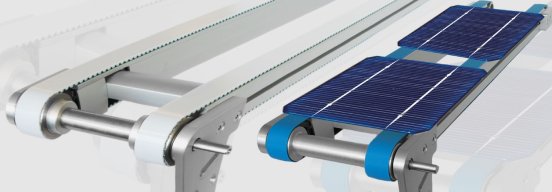

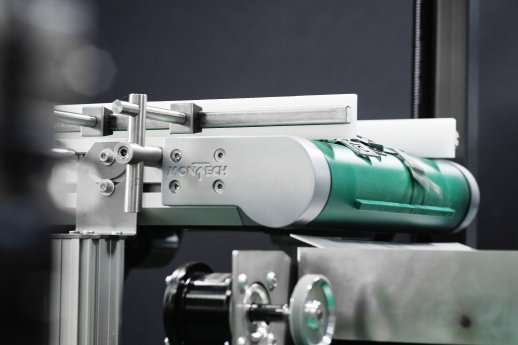

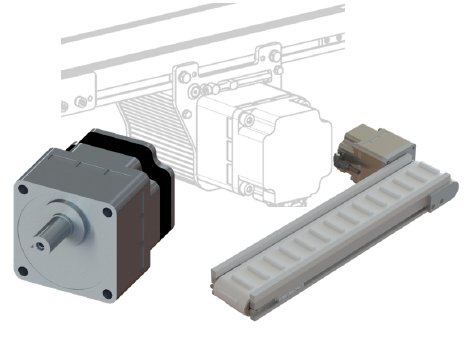

With Montech’s online configurator, designing your custom conveyor is just a few clicks away. Easily adjust the conveyor width, side guides, and structure to meet your specific needs. Download a quote with 3D CAD files from the cart or place your order directly. Fast, easy, and efficient!