At the end of 2017, wind power equipment generating a total of nearly 540 gigawatts was installed across the globe. Even though the increase of wind power in Germany is currently slowing, it is still on the upswing worldwide. In China, the country with the greatest installed wind power output, it was 217 gigawatts in mid-2019. By 2030, Great Britain wants to get a third of its energy from offshore wind parks and the USA, as well as many other countries, are increasing their wind power output. "In order to increase the energy yield, the towers of wind turbines are currently growing higher and the blades longer. New and increasingly demanding offshore sites keep getting added", explains Andreas Löffler, from the Business Development Composite department at FreiLacke. "However, the turbines can no longer be produced more cheaply in the way they are manufactured now because the quality cannot be reduced further. That means new concepts for the turbines are needed – fresh, innovative solutions are in urgent demand!"

The system concept has to be continued constructively

For its customers in the wind power sector, FreiLacke is keeping coating systems for all components – from the foundation to the rotor blades – in stock. In order to help them keep the costs of power generation low and to minimise their CO2 footprint, the manufacturer from the Black Forest has developed new concepts for coating and building the components. "With our system coatings, we are already offering a complete package to our customers that allows them to coat different surfaces with the same quality and the same colour. We are now extending this system concept far beyond coatings and are also advising manufacturers on the design and construction of individual components", adds Löffler.

Looking at challenges differently

But that requires production processes to be completely rethought. New process technologies are supposed to lead to less expensive plant maintenance, which would reduce production costs and therefore also the costs of generating electricity. That is why FreiLacke's development team also thinks about multi-material combinations and their optimal coordination – for example the way in which liquid and powder resins interact. "Powder has not yet been used in wind power plants", says Löffler. However, it is always worth looking at processes from a different perspective from time to time: For example, by thinking about the substrates together with the coating solutions. That is how FreiLacke offers process competence and support from a single source.

"Our advantage is that we have all raw materials for liquid and powder coatings and resins in stock and, thanks to our expertise, we can use these materials to develop new solutions", emphasises the wind power expert. By improving process steps during value creation, an increase in efficiency and profitability can be achieved. This will increasingly turn wind power into a truly green energy source.

Innovation 1: A new combined coating system for onshore towers

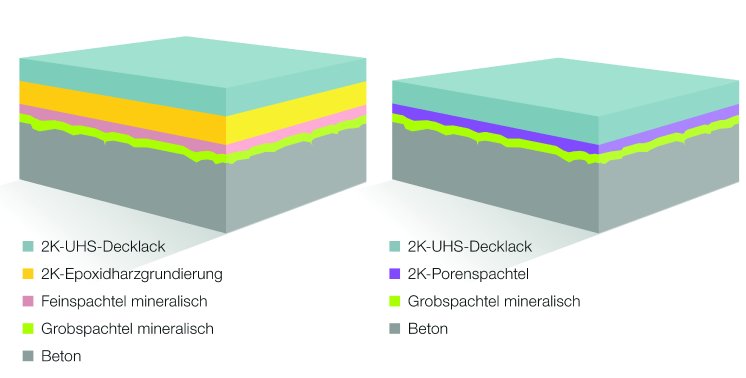

Most wind turbines are already taller than 100 metres. In the case of onshore systems, the towers mostly consist of individual concrete segments that are placed on top of each other and then braced. However, concrete is a highly alkaline material: When rain or other acidic media penetrate the concrete at the seams, this can lead to so-called "concrete bleeding", which not only leaves behind visible damage but can also jeopardise the long-term stability of the turbine. That is why a careful, complete coating of the individual rings of concrete is absolutely essential, for example with a FreiLacke functional coating consisting of a water-soluble 2C epoxy primer or a 2C polyurea primer filler as well as a 2C polyurea top coat. Additional combinations with other systems are also possible. In combination, they are designed to prevent these problems and the associated follow-up costs. These combinations are also well-suited for the coating of the foundation.

The 2C epoxy primer is practically solvent free, can easily be applied with a roller and has a high degree of adhesion even on fresh concrete. In combination with the primer filler and/or the 2C polyurea top coat, it provides maximum resistance against humidity and can be processed between 5 and 40°C.

The 2C polyurea top coat can be processed easily and, in addition to the even surface structure, it features very high light and weather resistance properties. Depending on the specifications of the surfaces, only a single layer has to be applied. The top coat hardens quickly, is highly scratch and chemical-resistant and can be transported shortly afterwards. It is practically VOC-free and can be overcoated with itself. The product has already been tested and successfully used in different climates.

Innovation 2: New process technology for the nacelle

The nacelle of a wind turbine houses the drive train with rotor hub, rotor shaft and generator as well as additional components. This "machine house" consists of plastic and is mainly manufactured nowadays in a manual laminating process. In order to coat the nacelle, and therefore make it weather resistant, a gelcoat is first introduced to the mould as an in-mould coating system. Conventional gelcoats are considered to be problematic for the environment because they contain styrene, an easily polymerisable monomer that is flammable and hazardous to human health. It irritates the airways, skin, eyes and mucous membranes. Styrene-free options have been very expensive until now.

In order to provide the wind power sector with a viable, inexpensive alternative, FreiLacke has worked on the development of solutions for nacelles. Using light construction, they consist of sandwich systems that can be coated with liquid and powder coatings. This styrene-free design not only significantly reduces the weight, but also increases the occupational safety of employees and the sustainability of the turbine. Traditional liquid products used in sheet construction or powder coatings – if their use had already been anticipated in the production process – can be used for coating.

All rotor blade components from a single source:

1) Traditional composites / CM powder / metallic

2) Filler / bonding agent (metal and plastic) / pore filler

3) GelCoat

4) Top coats (water-thinnable, solvent-based)

5) Erosion protection (LEP)

Innovation 3: Modular edge protection

The rotor blades of state-of-the-art wind turbines are spinning at top speeds of significantly more than 300 km/h. The aerodynamic profile at its front edges plays an important role because it contributes significantly to the effectiveness of the turbine. However, these front edges are especially prone to erosion: Environmental influences, such as rain, snow, hail, sand and UV radiation as well as severe temperature and moisture fluctuation, can sharply accelerate this erosion. In the case of offshore turbines, the humidity and salinity they are exposed to can add further strains.

That is why the corrosion resistance requirements are particularly high and a high-performance edge protection coating, which is also referred to as leading edge protection (LEP), is extremely important. They significantly delay the corrosive effect while the aerodynamic profile geometry for the laminar air flow is maintained longer. The result is an improved turbine efficiency and longer maintenance intervals.

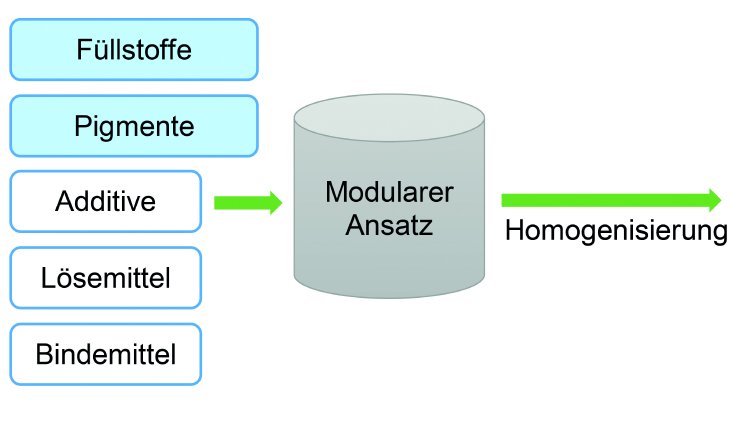

FreiLacke already has multiple leading edge protection systems available for its customers in the wind energy sector. "In addition, our new, cutting-edge production technology only homogenises instead of dispersing", explains Lena Sühling from FreiLacke's Composites Development.

The benefits are obvious: Modular coating recipes only contain liquid components, can be dosed fully automatically and can be produced more quickly, which means that FreiLacke can faster react to customer requests. "In addition, the modular production facilitates a greater reproducibility – regardless of batch sizes and production locations. This is advantageous because rotor blade manufacturers have long been producing globally", emphasises Sühling.

Innovation 4: Ensuring the long-term use of hubs and generators

The hub is one of the most important design components of a wind turbine: This is where the rotor blades meet and it is subject to tremendous forces. It drives the generator in the interior of the housing and thereby keeps the energy production going.

The surfaces of the outer components of the hub and generator consist of steel, for which FreiLacke provides innovative powder coating, high-solid and ultra-high-solid coating systems. Based on these systems, component-specific requirements, such as a high corrosion protection as well as maximum resistances regarding temperature as well as chemical and mechanical influences, can be implemented. FreiLacke supports manufacturers in the development of a surface specification as well as in the qualification of suppliers and the execution of acceptance tests. Upon request, it will also create original samples and target value samples for subsidiaries and suppliers. In addition, it will prepare work instructions and conduct training sessions.

Summary

FreiLacke provides the manufacturers of wind turbines and their components with high-quality resin and coating systems from a single source. Thanks to its many years of experience, FreiLacke uses highly innovative and promising approaches and advises its customers on the process technology of individual components. That contributes to further increasing the savings potential of the already environmentally friendly wind power.