Strong trio of plastics for medical technology

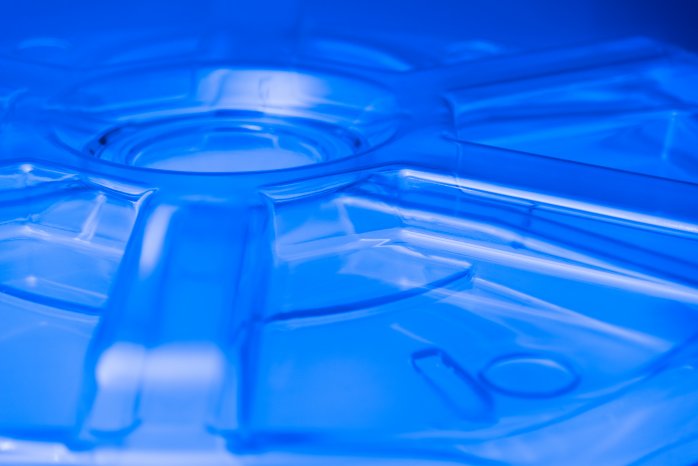

From dental splints and rigid medical packaging to containers and trays for medical devices. Exolon Group is presenting the entire Med-Range – Exolon® Med, Vivak® Med and Inspria® Med – for the first time at K. All Med-Range products consist of 100% virgin material that meets the requirements of ISO 10993 for the biological evaluation of medical devices. The sheets are produced in accordance with good manufacturing practices (GMP). The manufacturing process is subject to constant control by a quality management system that meets the ISO 9001:2015 standard. Processors can thus trace the sheet material down to the raw material – an important basis for the further documentation of future end products.

Innovation for Building & Construction

With Exolon® multi UV Hybrid-X, the Exolon Group is presenting a completely new multiwall sheet type. The new geometry is a complex combination of walls and air chambers. The sheets are therefore all-rounders with high energy-saving potential. They offer excellent thermal insulation and improved light diffusion, and also have strong mechanical properties with optimised area weight. Their low heat transfer coefficient (Ug) impresses with energy savings of more than 30 percent compared to standard sheets available on the market.

This means a saving of around three litres of heating oil or 2.5 cubic metres of natural gas per square metre and year. The sheet material meets all quality standards in terms of fire protection with a CE mark in accordance with EN 16153 and DIN ISO 9001 for quality management.

Hard-coating for extreme situations

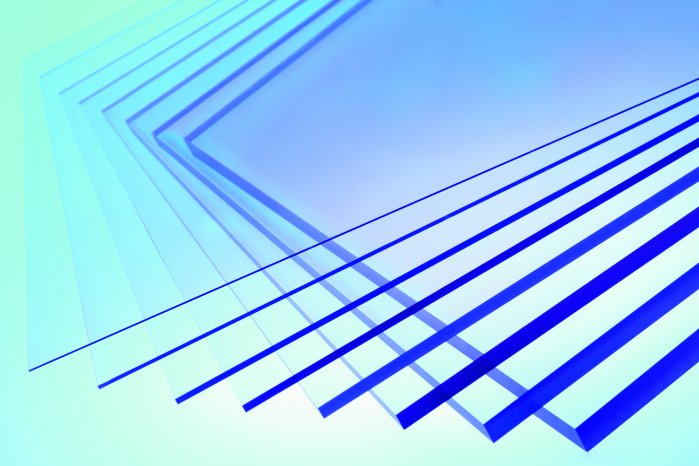

The AR (abrasion-resistant) solid sheet range consists of various types of particularly wear-resistant, chemical- and UV-resistant polycarbonate sheets. Combined with outstanding breaking strength and a surface quality comparable to glass, the material impresses with its high resistance to scratches and abrasion.

With the AR 5 and AR FO product types, the Exolon Group is now expanding its range of hard-coated polycarbonate sheet material. While Exolon AR can only be installed flat, the new types can be formed despite the coating. Subsequent offline coating processes are unnecessary and the resulting follow-up costs can be saved.

Depending on the area of application, the sheets have coating on one or both sides. All sheets come with a 10-year warranty of unbreakability. The guarantee against delamination and weathering varies depending on the type of sheet and area of application.

Focus on sustainability

Ecology, recycling economy, sustainability – these are terms that have become ubiquitous today and are part of our future. In the plastics industry, these goals are achieved through the reuse of raw materials, among other things. Under the name Eco, the Exolon Group is launching new products on the market in which recycled materials are processed. Vivak® GP Eco and Exolon® GP Eco consist of at least 40 per cent ground material from our own production. At the same time, the company reduces the amount of waste through reuse and upgrades this ground material to a high-quality sheet material.

The next step towards an eco-friendly future goes hand in hand with the ISCC Plus (International Sustainability & Carbon Certification) certification, which the Exolon Group has already received. For rEcoPlus products, the mass-balance approach is being pursued, whereby renewable raw materials are already used at the beginning of the production chain as a replacement for fossil raw materials.

Experienced trade fair debutant

The division formerly belonging to the Covestro Group will be exhibiting at the K trade fair for the first time. Since it was founded as a medium-sized company in 2020 under the umbrella of the Serafin Group of Companies, the Exolon Group has carried out a comprehensive product and brand relaunch.

At the Exolon Group trade fair stand, visitors to K 2022 can get to know the company and its wide range of products. The Exolon Group trade fair team welcomes you to Hall 8b, Stand F30.