The Russian company OMK Vyksa is one of the largest manufacturers of pipeline pipes in the world. Previously, Vyksa had partially purchased required pipe couplings for the production of its pipes. In order to produce faster and more flexibly and to be able to offer the complete product range from a single source, Vyksa built a modern production line for manufacturing pipe couplings. The two fully automatic coating lines for coating, signing and marking pipe couplings on an area of 15.8 x 29 meters fit seamlessly into the newly built production hall. The complete manufacturing process of pipe couplings can thus take place in one production hall. "When planning the new plant technology, it was important for us that all manufacturing processes are integrated in one hall. Short distances for maximum efficiency. The engineers of Venjakob fulfilled this important criterion with this compact system", says Dimitriev Alexander Michailowitsch, project manager OMK Vyksa.

The right program for each coupling type

The self-manufactured pipe couplings are not only to be used for the company's own needs, but also to be sold to enterprises that do not have their own coupling production. "This requires a certain flexibility of the finishing line. On the one hand, the workpiece carriers had to be designed in such a way that they could accommodate different sizes of couplings. On the other hand, the automated marking and signature process had to take into account different standard specifications and the possibility of individualization," says Kornelius Berg, sales engineer at Venjakob Maschinenbau, describing the challenge.

The coloring of the shell surface and the ring marking as well as the signing of the coupling comply with the valid API and GOST standards. To ensure that the system can be set up quickly and easily for different types of couplings, the Venjakob team has created a separate program menu for each type of coupling. This menu is stored in the control system and can be easily accessed by the machine operator. For individual signatures, the machine operator has an easily accessible keyboard panel directly on the marking system (Jet System), into which he can independently enter the desired data for the next batch of couplings.

Coating in intervals of a second

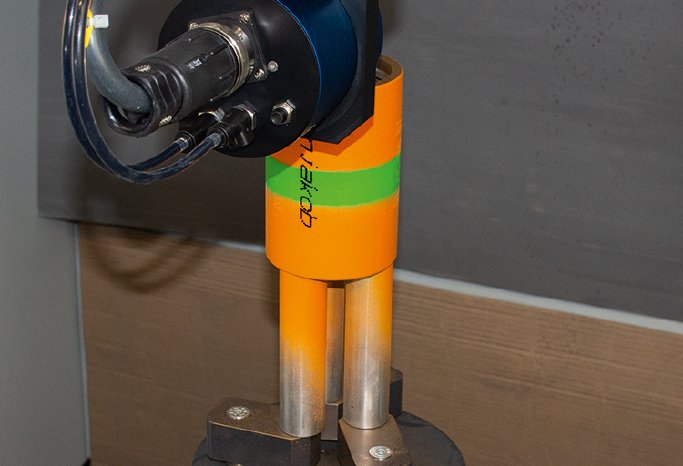

The entire coating process - from loading at the feeding station through the individual processing stations to removal - takes place completely without external intervention. The conveyor technology used for the fully automatic handling, including the control technology, was planned, developed and manufactured by Venjakob and installed at Vyksa. The plant is designed for a wide range of pipe coupling types. Round pipe couplings with an outer diameter of 73 mm to a maximum of 450 mm, a length of 100 mm to a maximum of 330 mm and a weight of 2.34 kg to 47 kg can be processed. The capacity of the machine is in relation to the diameter and length of the couplings. The maximum output is 225 couplings per hour, which corresponds to a cycle time of 16 seconds per coupling. With the largest coupling type, the output would be 60 couplings per hour, which corresponds to a cycle time of 60 seconds per coupling. The average cycle time for a coupling of 300 mm diameter and 250 mm length is 25 seconds.

The process

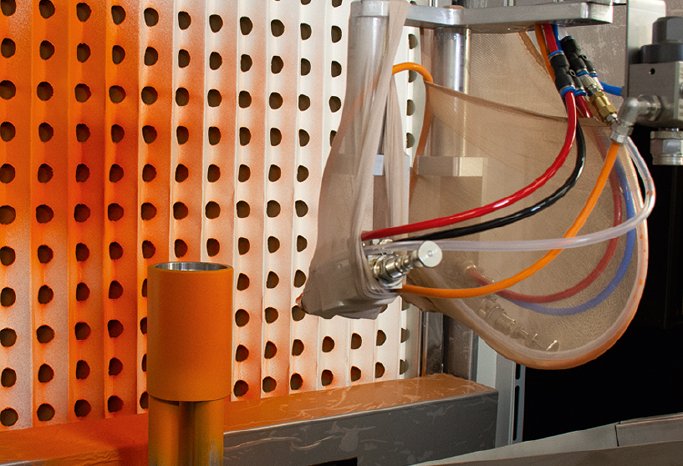

Loading and placing on workpiece carriers: In the first step, the pipe couplings are automatically arranged in several layers one above the other in a container. The couplings are removed from the container in rows, placed on the turning station and then placed vertically. They are then transported to the loading portal via a chain transport system. From here the pipe couplings are placed individually on the workpiece carriers. These can be infinitely adjusted to the desired size of the pipe couplings - the spindle holders are positioned closer or further together.

Coating, marking and signing process with preparation of the couplings:

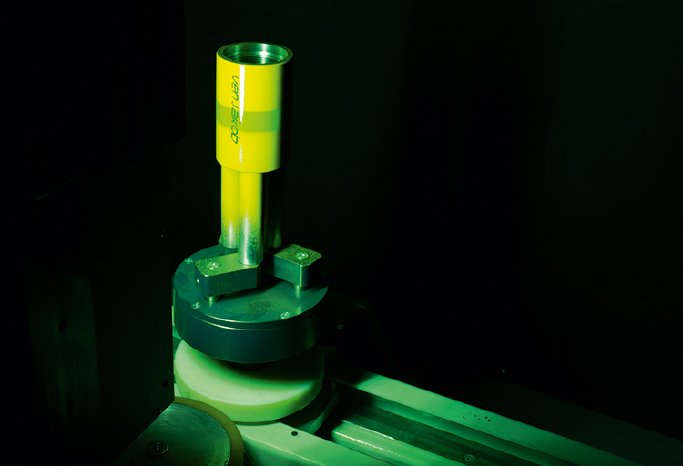

Preheating, external and internal coating and hot air drying take place in closed systems on a spindle chain conveyor. During preheating, the temperature is increased to 10 °C up to 15 °C. Afterwards follows the shell coating with a solvent-based lacquer. A total of 11 colors are available, which are applied with spray guns. The couplings pass through a drying section and are again fed to the spray coating machine for the ring strip marking.

Here each color has a different meaning, which is defined in the corresponding API or GOST standard. After another drying process, the couplings are transported to the jet system for signing the outer surface. The marking in black or white can be entered individually via a keyboard panel. After a further drying phase, a UV clear coat is applied to protect the signature during transport. The clear lacquer is cured by means of UV lamps.

Internal threads are protected against corrosion: After the external coating is completed, the pipe couplings are placed on the workpiece carriers for the internal coating. The couplings are then transferred to another spindle chain conveyor for the internal coating. Also in a closed system, the thread conservation is carried out with an oil-water emulsion.

Unloading and loading directly next to each other: After the subsequent hot-air drying, the finished pipe couplings are placed on the outfeed conveyor belt and fed to the turning station for collection. Finally, the turned pipe couplings are deposited in rows - by means of a magnetic gripper portal - in several layers into the removal container.

Special features of the pipe coupling coating line at a glance

- fully automated handling;

- flexible design to suit different types of pipe couplings;

- individual signing and marking options - in accordance with the standard specifications;

- UV clear coat application for corrosion and protective coating of the shell surface

- thread conservation with oil-water emulsion;

- thread coating as corrosion and sliding finish;

- fast throughput of the pipe couplings;

- seamless integration into the entire manufacturing process;

- compact, modular design.