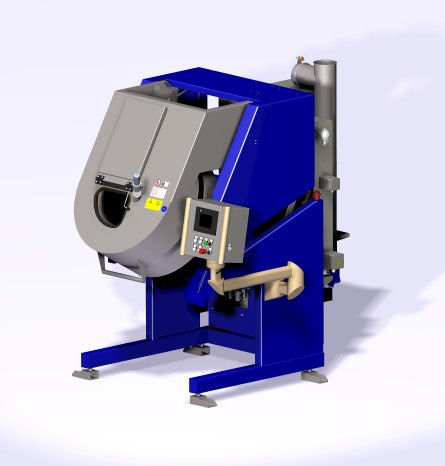

With a drum diameter of 800 mm and a usable volume of 50 l the new machine can accommodate batches of 50 kg. This is of particular interest to customers, who must coat parts with complex geometries or heavy parts, which, for example are made from metal.

With technical features like optimized fresh air inlet and a modular filter system – up to filter class F6 – this machine offers a high degree of flexibility regarding the use of different paints with, at the same time, a higher throughput. By being able to use more solvent the users can speed up the coating process and still remain within the ATEX limits.

First reports from the field indicate that the new coater so far has not only fully met but exceeded expectations.

By optimizing the airflow and the paint spraying system, Walther Trowal was able to keep overspray at an absolute minimum. And finally, the new heat control system helps reduce cycle times and energy consumption.

Walther Trowal at Paint Expo 2016

(April 19 - 21, Karlsruhe/Germany):

Hall 2, Booth 2310